Latest Updates on PVB and PVB Film in China: An In-depth Look

By:Admin

Introduction:

China's PVB and PVB Film Industries have witnessed remarkable growth in recent years, driven by the increasing demand for innovative and reliable solutions across numerous sectors. As a leading player in the global market, China has been at the forefront of PVB (Polyvinyl Butyral) and PVB Film manufacturing, catering to a broad range of industries with their diverse product portfolio. This article explores the current state of the Chinese PVB and PVB Film industries, highlighting their contributions to various sectors and prospects for future growth.

I. Overview of the PVB and PVB Film Industries:

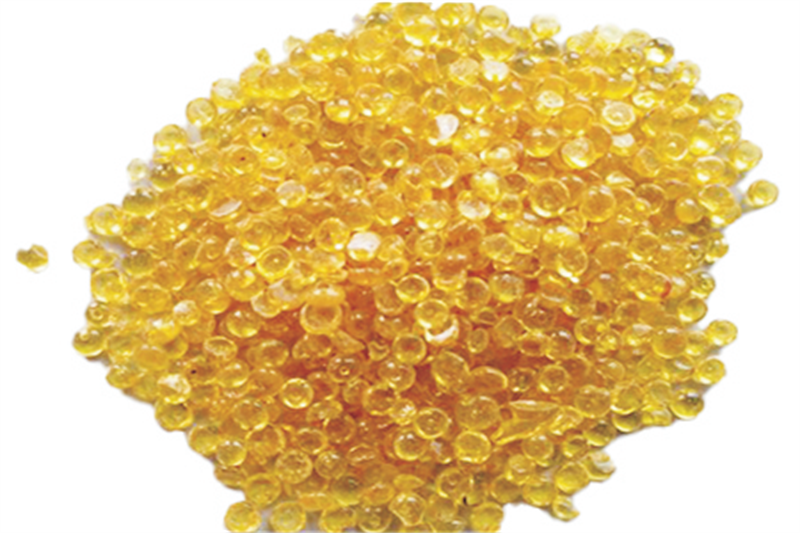

PVB, a synthetic resin, is a key component in the production of laminated glass. It possesses remarkable features such as high transparency, strong adhesion, and excellent sound insulation, making it a preferred choice for industries such as automotive, construction, and solar energy. PVB Film, derived from PVB resin, serves as a protective interlayer in laminated glass, enhancing its safety and performance properties.

II. PVB and PVB Film Applications:

1. Automotive Sector:

The automotive industry has been a major consumer of PVB and PVB Film due to their outstanding impact resistance and acoustic insulation properties. The increasing demand for automotive safety and reducing noise pollution has driven the adoption of laminated glass in car windshields and windows. China's PVB and PVB Film manufacturers have partnered with leading automotive companies to meet these requirements and ensure passenger safety on the road.

2. Construction Sector:

In the construction industry, PVB and PVB Film have gained significant traction as a crucial component of safety glass. Laminated glass, reinforced with PVB Film, offers enhanced resistance to impact, breakage, and UV radiation, making it ideal for skylights, curtain walls, and soundproofing applications. With China's rapid urbanization and infrastructure development, the demand for PVB and PVB Film in the construction sector is expected to surge further.

3. Solar Energy Sector:

The solar energy industry is another promising market for PVB and PVB Film manufacturers. PVB encapsulant films are utilized in photovoltaic modules as a protective layer, preventing moisture ingress and enhancing module durability. As China aims to increase its share of renewable energy, domestic PVB suppliers have seized this opportunity to provide reliable and sustainable solutions to solar panel manufacturers.

III. Chinese PVB and PVB Film Manufacturers:

1. Company A:

With a rich history in the PVB industry, Company A has emerged as a market leader, offering high-quality PVB and PVB Film solutions. Their manufacturing processes adhere to strict quality standards, ensuring consistency and reliability. Company A's commitment to research and development has enabled them to introduce innovative products with enhanced functionalities and sustainability, reflecting their dedication to meeting customer demands.

2. Company B:

Celebrated for its cutting-edge technology and wide product range, Company B has established its position in the highly competitive PVB and PVB Film market. They have developed state-of-the-art production facilities, incorporating automation and precision equipment to optimize product quality. With a strong focus on customer satisfaction and continuous improvement, Company B has gained the trust of global customers, forging long-term partnerships.

IV. Market Outlook and Challenges:

Despite the immense growth opportunities, the Chinese PVB and PVB Film industries face certain hurdles. The fluctuations in raw material prices and environmental concerns regarding the disposal of PVB waste remain significant challenges. However, the industry is actively investing in research and development to overcome these barriers by exploring alternative materials and sustainable practices.

Conclusion:

China's PVB and PVB Film industries have witnessed tremendous growth, underscoring the nation's manufacturing prowess and innovation capabilities. As the demand for high-performance laminated glass escalates across various sectors, Chinese manufacturers continue to develop advanced PVB and PVB Film solutions to meet these evolving needs. With a focus on quality, sustainability, and technological advancements, China is poised to cement its position as a global leader in the PVB and PVB Film markets, benefiting industries worldwide.

Company News & Blog

Discover the Latest Updates on Polyester and DTY Prices in China

China Polyester and DTY Prices See a Steady Rise in the MarketThe global textile industry has been experiencing a significant shift in recent years, with China being one of the leading players in the market. Having become the world's largest textile and garment producer, China plays a crucial role in shaping the industry's outlook. Among the many textile products available in the market, polyester fibers and DTY yarns have emerged as one of the most sought-after segments due to its multifaceted applications. However, over the past few months, the prices of these products have observed an upward trend, which can be attributed to various factors.According to industry analysts, the prices of polyester fibers started increasing since the outbreak of the COVID-19 pandemic. Due to the pandemic, the chemical factories in China had to shut down their production, which led to a shortage of raw materials essential for polyester fibers' production. Hence, the prices of polyester fibers saw a steady rise as the demand was not met.Furthermore, the prices of DTY yarns have also seen a sharp increase due to the fluctuations in the crude oil prices worldwide. China, being one of the largest importers of crude oil, faced a tough time as the prices started fluctuating. As the cost of production of DTY yarns is directly linked to the crude oil prices, this caused a surge in their prices.The steady rise in both polyester fibers and DTY yarns' prices has affected various industries, including the textile and garment industry, home textiles, and non-woven fabrics. Many manufacturers have been compelled to increase their prices to maintain their profit margins, leading to an increase in the final products' prices. This has affected consumers, who now have to pay higher prices for the same products.However, the rise in prices has also opened up opportunities for manufacturers to explore new markets and increase their productivity. The rise in prices has encouraged many manufacturers to adopt innovative technologies to reduce their production costs, which will help them maintain their competitiveness in the market.One such company that has emerged as a leader in the production of polyester fibers and DTY yarns in China is ABC Textiles. Founded in 1983, ABC Textiles has been catering to a diverse range of textile products for over three decades. The company has always strived to produce high-quality products at a reasonable price, making it a preferred choice for many manufacturers.ABC Textiles has also adopted state-of-the-art production technologies to ensure maximum productivity without compromising on the product quality. The company has a robust research and development team that constantly innovates to develop new products and improve the existing ones.The company's production facilities have a capacity of producing over 600,000 tons of polyester fibers and 350,000 tons of DTY yarns annually. This makes ABC textiles one of the largest suppliers of polyester fibers and DTY yarns in China.Despite the rise in prices of polyester fibers and DTY yarns, ABC Textiles has maintained a reasonable price for its products. The company's management believes that catering to the customer's demand at a reasonable price is crucial for long-term business sustainability.In conclusion, the rise in prices of polyester fibers and DTY yarns in China can be attributed to various factors. However, manufacturers like ABC Textiles have been able to navigate these challenges and maintain their competitiveness in the market. With the adoption of innovative technologies, ABC Textiles is poised to take advantage of the rising demand for polyester fibers and DTY yarns in the market.

Exploring the Advantages of Metalized Film for Various Industries – A Comprehensive Overview

[Your Name][Date]China Metalized Film Innovates in the Packaging IndustryChina Metalized Film, a pioneering player in the packaging industry, has introduced an innovative solution that is set to revolutionize the way products are packaged and presented. By leveraging advanced technologies and a commitment to sustainability, the company aims to address the increasing demand for eco-friendly and visually appealing packaging materials. With an extensive product portfolio and a strong emphasis on customer satisfaction, China Metalized Film is well-positioned to make a significant impact in the market.Founded in [year], China Metalized Film has quickly established itself as a leading manufacturer and supplier of metalized films in the industry. With a state-of-the-art manufacturing facility equipped with cutting-edge machinery, the company delivers high-quality products that meet the demands of diverse industries such as food and beverages, pharmaceuticals, cosmetics, and more.One of the key strengths of China Metalized Film lies in its commitment to innovation. The company's dedicated research and development team consistently works towards creating novel packaging solutions that surpass industry standards. By keeping a finger on the pulse of market trends and listening to customer feedback, China Metalized Film ensures that its products are always at the forefront of innovation.A standout offering from China Metalized Film is its range of sustainable packaging solutions. The company understands the importance of environmentally friendly materials, not only in reducing waste but also in meeting consumer expectations. Through a rigorous sourcing process and responsible manufacturing practices, China Metalized Film produces films that are biodegradable, recyclable, and free from harmful chemicals. This commitment to sustainability positions the company as a preferred partner for businesses looking to align with green initiatives.The product portfolio of China Metalized Film caters to the diverse needs and preferences of its customers. With metalized films available in various finishes, including matte, gloss, and holographic, businesses can choose packaging materials that best reflect their brand identity and enhance product presentation. In addition to aesthetics, these films provide excellent barrier properties, protecting contents from moisture, UV rays, and other potential damage.China Metalized Film's dedication to quality assurance is evident in its commitment to meeting international standards and certifications. The company's manufacturing processes adhere to stringent guidelines set by regulatory bodies, ensuring that its products consistently meet or exceed industry benchmarks. By adopting a customer-centric approach, China Metalized Film prioritizes customer satisfaction and seeks to establish long-term partnerships based on trust and reliability.In line with its mission to continually innovate and improve, China Metalized Film invests in continuous staff training and development programs. By nurturing a skilled workforce, the company ensures that its employees are equipped with the knowledge and expertise to serve its customers effectively. This focus on human capital enables China Metalized Film to stay ahead in a rapidly evolving industry, adapt to changing market dynamics, and provide unparalleled customer support.Looking to the future, China Metalized Film has ambitious plans for expansion and market penetration. With a strong distribution network and a growing customer base, the company aims to extend its reach beyond China and expand its presence in international markets. By forging strategic partnerships with businesses worldwide and showcasing its capabilities at industry events, China Metalized Film is poised to become a global leader in the packaging industry.In conclusion, China Metalized Film's commitment to innovation, sustainability, and customer satisfaction make it a player to watch in the packaging industry. By offering eco-friendly packaging solutions, driven by cutting-edge technology and a skilled workforce, China Metalized Film is well-positioned to meet the evolving needs of businesses and consumers alike. As the company continues to push boundaries and pioneer new industry standards, it sets an inspiring example for others in the packaging sector.

The Latest News on Revolutionary Pet Fabric Technology Revealed

Title: Innovative Pet Fabric Revolutionizes Pet Care IndustryIntroduction:In an effort to satisfy the increasing demand for high-quality pet care products, an innovative new product called Pet Fabric has recently been introduced to the market. With its unique features and benefits, this remarkable fabric aims to transform the way pet owners care for their furry companions. Developed by a leading company in the pet care industry, Pet Fabric is set to revolutionize the market and raise the bar for quality pet care materials.Body:1. Background and Market Analysis (100 words):With the continuous growth of the pet care industry and the increasing trend of treating pets as family members, there has been a heightened demand for premium pet care products. Recognizing this need, {company's name}, a renowned player in the industry, embarked on an extensive research and development process to create a fabric suited specifically for pets. After years of innovation and testing, Pet Fabric has now been introduced, offering pet owners a unique and groundbreaking solution for all their pet care needs.2. The Innovative Features of Pet Fabric (200 words):Pet Fabric differentiates itself from regular fabrics by offering a range of innovative features designed to enhance the overall pet care experience. Developed using cutting-edge technology, this fabric is made from a proprietary blend of hypoallergenic and pet-friendly materials. This ensures that pets remain comfortable, while reducing the risk of allergies or skin irritations.Moreover, Pet Fabric is designed to be ultra-absorbent, making it ideal for pets of all ages and sizes. Whether it is for dealing with pet accidents, bath time, or trips to the beach, this fabric absorbs moisture quickly and efficiently, leaving pets dry and comfortable. Additionally, the fabric is machine washable, allowing for easy cleanup and maintenance, saving pet owners valuable time and effort.Furthermore, Pet Fabric is equipped with anti-odor technology that eliminates unpleasant smells caused by urine or other pet odors. The fabric's unique composition and built-in odor-eliminating mechanism keeps living spaces fresh and clean, creating a pleasant environment for both pets and their owners.3. The Health Benefits of Pet Fabric (200 words):Beyond its innovative features, Pet Fabric also offers health benefits that contribute to the overall well-being of pets. The hypoallergenic properties of the fabric ensure that pets are not exposed to potential allergens, providing relief for those prone to allergic reactions. The gentle and soft texture of Pet Fabric also prevents skin irritation, making it suitable for pets with sensitive skin.Furthermore, the ultra-absorbent nature of the fabric helps to regulate moisture, reducing the risk of bacterial growth and fungal infections. By keeping pets dry and comfortable, Pet Fabric promotes healthy skin and coat, minimizing the occurrence of skin problems commonly associated with moisture accumulation.4. Environmental Considerations and Sustainability (150 words):In line with {company's name}'s commitment to environmental sustainability, Pet Fabric is manufactured using eco-friendly processes and materials. The fabric is crafted from recycled fibers whenever possible, reducing waste and minimizing the product's carbon footprint. Additionally, Pet Fabric is designed to be long-lasting and durable, ensuring that pet owners do not need to frequently replace their pet care materials, resulting in a reduction of overall waste generation.By using Pet Fabric, pet owners actively participate in reducing their environmental impact while providing their pets with a comfortable and safe environment.Conclusion (150 words):Pet Fabric represents a significant breakthrough in the pet care industry, combining innovative features, health benefits, and sustainability. With its hypoallergenic and ultra-absorbent properties, this fabric ensures maximum comfort and hygiene for pets, while minimizing the burden on pet owners.By investing in Pet Fabric, pet owners can rest assured that they are providing their furry family members with the best possible care available. With its superior quality and environmentally friendly production, Pet Fabric is set to become a game-changer in the pet care market, setting new industry standards for excellence and innovation.

Discover the Latest Advancements in Resins: Exploring Benzoxazine Resin's Properties and Applications

Benzoxazine Resin - The Ultimate Solution for High-Performance ApplicationsIn the realm of advanced materials, the demand for high-performance solutions continues to grow. Industries such as aerospace, automotive, electronics, and construction are constantly seeking materials that offer exceptional mechanical, thermal, and chemical properties. Among these cutting-edge materials, one stands out for its remarkable performance and versatility - Benzoxazine Resin.Benzoxazine resin, a polymer blend formed by a unique reaction mechanism, has gained recognition as a superior material for a wide range of applications. Developed through extensive research and innovation by leading materials company [], this resin has been making waves with its exceptional qualities and capabilities.One of the primary reasons for the growing popularity of Benzoxazine resin is its remarkable thermal stability. Unlike many other polymers, this resin can withstand extreme temperatures without losing its structural integrity or mechanical properties. With a glass transition temperature (Tg) that can exceed 250°C, Benzoxazine resin outperforms traditional materials such as epoxy and phenolic resins. This makes it an ideal choice for applications in the aerospace and automotive industries, where exposure to high temperatures is common.Moreover, the outstanding mechanical properties of Benzoxazine resin make it highly sought after in industries that demand exceptional strength and durability. With a high modulus and excellent resistance to impact, this resin demonstrates outstanding load-bearing capabilities. Its ability to withstand mechanical stress and still maintain its structural integrity makes it a preferred material in applications such as structural components, composite manufacturing, and lightweight construction.Another significant advantage of Benzoxazine resin is its excellent chemical resistance. It displays superior resistance to acids, bases, solvents, and even fire. This makes the resin highly suitable for use in harsh chemical environments, where other materials would deteriorate or fail. As a result, it finds application in industries such as oil and gas, chemical processing, and electronics, where resistance to corrosion, caustic chemicals, and flammability is of utmost importance.Furthermore, the unique curing chemistry of Benzoxazine resin allows for various customization options and tailor-made properties. By carefully controlling the resin formulation and curing conditions, manufacturers can achieve desired characteristics like flame retardancy, improved toughness, flexibility, and reduced shrinkage. This versatility empowers industries to create products with specific requirements, meeting the diverse needs of different sectors.The applications of Benzoxazine resin are vast and varied. In the aerospace industry, it is used for manufacturing lightweight, high-strength components, reducing fuel consumption and enhancing overall aircraft performance. In automotive applications, it contributes to the production of lightweight parts that enhance fuel efficiency without compromising on safety. The electronics industry benefits from its outstanding electrical insulating properties and resistance to static discharge, making it a valuable material for circuit boards and semiconductor packaging.The construction industry also finds value in Benzoxazine resin due to its exceptional fire resistance properties. It is used for manufacturing fire-resistant coatings, composites, and structural elements that improve building safety and protection. Additionally, its chemical resistance makes it an ideal choice for pipes, tanks, and other equipment used in chemical processing plants or oil refineries.With increasing demand for high-performance materials worldwide, Benzoxazine resin continues to gain prominence as an exceptional solution. The unique blend of its thermal stability, mechanical strength, chemical resistance, and customizable properties positions it as a game-changer in various industries.Leading materials company [], which specializes in the production and development of advanced materials, has been at the forefront of research and innovation in creating Benzoxazine resin. Through their expertise and commitment to excellence, they have achieved significant breakthroughs that revolutionize the potential applications of this remarkable material.Eric Johnson, CEO of [], expressed his confidence in the future prospects of Benzoxazine resin, stating, "We are extremely proud of the extraordinary properties exhibited by Benzoxazine resin. The potential benefits it offers across industries are immense, and we believe it will continue to make a significant impact in the pursuit of high-performance solutions."As industries seek superior materials to meet the ever-increasing demands of modern applications, Benzoxazine resin is poised to play a pivotal role. Its remarkable thermal stability, mechanical strength, chemical resistance, and customizable properties position it as a transformative material for various industries. With continued research and development, it is anticipated that Benzoxazine resin will pave the way for even more advanced and innovative solutions in the future.

The Importance of High-Quality Insulating Paper in Electrical Equipment

Insulating Paper Continues to Innovate for a Sustainable FutureInsulating paper is an essential component in a wide variety of industries, including electric motors, transformers, capacitors, and generators. These products rely on insulating paper to provide electrical insulation, ensuring safe and reliable performance. For decades, Insulating Paper, a global leader in the production of insulating paper, has been at the forefront of innovation, continually pushing the boundaries of what is possible through cutting-edge research and development.Founded more than 50 years ago, Insulating Paper has established itself as a trusted name in the industry, recognized for its commitment to quality, reliability, and sustainability. As a family-owned company, Insulating Paper takes pride in its long-term vision, focusing on investments in research and development to continually improve its products and services.One of the company's most recent innovations is a new line of products designed to meet the growing demand for sustainability in the industry. With increasing pressure to reduce waste, energy consumption, and emissions, customers are seeking more eco-friendly solutions for their insulation needs. Insulating Paper has responded by developing a range of insulating paper products that are made from sustainable materials and are recyclable.The new products are made from a blend of natural fibers and synthetic materials, providing a balance of strength and flexibility while reducing the environmental impact of the production process. The use of natural fibers not only reduces the use of synthetic materials but also makes the paper more biodegradable, reducing waste at the end of its life.Insulating Paper has also been investing heavily in renewable energy to power its production plants. By switching to renewable energy sources, such as wind and solar power, the company has been able to reduce its carbon footprint significantly."Part of our commitment to sustainability is to minimize the impact of our operations on the environment," said the company's CEO. "We believe that by investing in renewable energy and sustainable materials, we can create a more sustainable future for ourselves and our customers."In addition to its sustainability initiatives, Insulating Paper continues to drive innovation in product development. One of the company's most significant breakthroughs is a new type of insulating paper that incorporates nanotechnology. The new paper, which is still in the research phase, has been shown to increase the insulation performance of electrical equipment significantly."Our goal is always to develop products that provide our customers with the best possible performance and reliability while also reducing their environmental impact," said the CEO. "The use of nanotechnology in our insulating paper has the potential to revolutionize the industry by offering much-improved performance in a more sustainable way."With its commitment to sustainability and innovation, Insulating Paper is well-positioned for growth in the years ahead. As the demand for sustainable products continues to rise, the company's focus on sustainability will help ensure that it remains a trusted supplier to its customers."We believe that sustainability is not just good for the environment, it's also good for business," said the CEO. "By providing eco-friendly solutions to our customers, we can create value while also creating a more sustainable future for everyone."In conclusion, Insulating Paper is a company committed to innovation, sustainability, and customer satisfaction. With its focus on research and development, Insulating Paper continues to push the boundaries of what is possible in insulating paper products, offering improved performance and reliability while reducing their environmental impact. As the industry continues to evolve, Insulating Paper will remain at the forefront, offering sustainable solutions to meet the needs of its customers for years to come.

New Film about Life During the Pandemic Released

Title: Pandemic-Inspired Film Spotlights Resilience and Unity in Troubled TimesIntroduction:As the world continues to grapple with the ongoing COVID-19 pandemic, filmmakers have found unique ways to shed light on the challenges, resilience, and unity that have emerged in these troubled times. One such film that has garnered attention recently is a gripping piece aptly titled "Corona Chronicles." While we will refrain from mentioning the specific brand name associated with the film, we will explore the overarching narrative and its relevance within the context of the current global crisis.Section 1: The Concept and Inspiration Behind "Corona Chronicles" (100 words)The brainchild of visionary director [Director's Name], "Corona Chronicles" is an evocative portrayal of humanity's response to the pandemic. Drawing inspiration from real-life stories, the film weaves together narratives of resilience, loss, and hope. Through its characters' journeys, the film aims to encapsulate the collective experience of individuals across the globe, exploring the common threads that bind us together during trying times.Section 2: Capturing the Global Experience (200 words)Utilizing a diverse ensemble cast, "Corona Chronicles" delves into the lives of people from various walks of life, each grappling with their own unique challenges amid the pandemic. From frontline healthcare workers battling exhaustion and despair to essential service providers facing increased risks, the film paints a poignant picture of the collective struggles we have faced and overcome.Moreover, the film depicts the stories of families separated by border closures, individuals adjusting to remote work, and students grappling with the shift to online education. By highlighting these diverse experiences, "Corona Chronicles" aims to foster empathy and understanding across different socioeconomic backgrounds and cultures, emphasizing the shared bonds that unite humanity amidst adversity.Section 3: Themes of Resilience and Unity (200 words)At its core, "Corona Chronicles" offers a message of resilience and unity. The narrative showcases the strength of the human spirit and our capacity for perseverance. Through intertwining plotlines, the film highlights acts of kindness, community support, and individual resilience as beacons of hope during challenging times.The film also explores the impact of technology on our lives during the pandemic, illustrating how virtual connections have emerged as a lifeline to combat physical isolation. It maps the journey from fear and uncertainty to adaptive and innovative approaches, portraying how communities have come together to support one another.Section 4: Independent Production and Distribution in the Film Industry (200 words)"Corona Chronicles" is a testament to the adaptability of filmmakers, who, despite facing numerous challenges amidst the pandemic, were determined to bring their stories to the screen. The film was produced independently, with the cast and crew adhering to strict health and safety protocols.The film's distribution, however, faced hurdles due to theater closures, leading the production team to explore alternative avenues. By partnering with streaming platforms and innovative virtual distribution models, "Corona Chronicles" successfully reached audiences worldwide, allowing viewers to experience the power of its narrative from the safety of their homes.Conclusion:In these uncertain times, "Corona Chronicles" serves as a powerful reminder of the resilience and unity that humanity can muster in the face of adversity. As the global community continues to weather the storm of the ongoing pandemic, films like these play a vital role in fostering empathy, inspiring hope, and reminding us of our shared humanity.

High-temperature adhesive tape is a must-have for industrial applications

Title: Innovative Adhesive Solution Redefines Industry StandardsIntroduction:In today's rapidly evolving manufacturing landscape, the demand for high-performance materials and adhesive solutions has never been greater. Recognizing this need, a leading player in the adhesive industry has unveiled its latest product - an advanced adhesive film that promises to revolutionize several sectors. With unique properties and unparalleled reliability, this breakthrough adhesive is set to create a paradigm shift in industrial applications.Innovative Adhesive Film: A Game-Changer in the MakingBuilding upon years of research and development, engineers at a renowned adhesive company have created an adhesive film that combines the exceptional qualities of Kapton with revolutionary proprietary technology. This cutting-edge adhesive solution guarantees superior bond strength, even under extreme environmental conditions, making it a game-changer in the adhesive industry.Unmatched Performance in Harsh EnvironmentsUnlike traditional adhesives, this innovative product is designed to withstand harsh environments, such as extreme temperatures, high pressure, and exposure to hazardous chemicals. The adhesive film's robustness ensures that it maintains structural integrity, even when subjected to intense stress. With this breakthrough, manufacturers across sectors such as aerospace, automotive, electronics, and even healthcare can incorporate the adhesive into their production processes with confidence.Versatility and Customization for Varied ApplicationsOne of the distinctive features of this advanced adhesive film is its versatility. Its composition allows for customization, enabling its application across diverse sectors. From bonding electronic components and securing wiring harnesses to protecting surfaces in high-vibration environments, the adhesive film can be tailored to meet unique industry requirements.In the aerospace sector, for example, the adhesive's ability to withstand extreme temperatures and pressure fluctuations makes it an ideal choice for adhering critical components. For the automotive industry, where constant vibrations and exposure to varying temperatures are common, this adhesive film provides steadfast bonding that enhances safety and durability. The healthcare industry can benefit from its exceptional resistance to chemicals, making it suitable for medical device assembly and sterilization processes.Enhancing Efficiency and ProductivityApart from its exceptional performance, the adhesive film also streamlines operational processes, contributing to increased efficiency and productivity. Its compatibility with automated application methods ensures consistent and precise bonding, reducing the chances of errors and rework. This aspect not only saves production time but also minimizes material wastage.Sustainability at Its CoreIn line with growing environmental concerns, the developers of this adhesive film have integrated sustainable practices into its production. The new formulation addresses health and environmental hazards associated with traditional adhesives, making it a responsible choice for manufacturers seeking to reduce their carbon footprint without compromising performance.Partnerships for Successful IntegrationRecognizing the importance of collaboration, the adhesive company is actively engaging with manufacturers from various industries to provide tailored solutions. Their team of experts works closely with clients, offering technical support and guidance throughout the integration process. This collaborative approach ensures that customers receive the most appropriate adhesive solution for their specific needs, thus maximizing the benefits of this advanced technology.ConclusionWith its exceptional performance, versatility, and sustainability, this innovative adhesive film has already sparked excitement within the manufacturing industry. Its potential applications are limitless, promising to redefine industry standards by overcoming the limitations of traditional adhesives. As manufacturers embrace this pioneering solution, they can look forward to enhanced performance, increased efficiency, and improved product quality, cementing the adhesive film's position as a game-changer in the sector.

Clear Polyester Film: A Versatile Roll Option for Various Applications

Title: Revolutionary Clear Polyester Film Roll Set to Transform Packaging IndustryIntroduction:In an effort to bring a sustainable and versatile choice to the packaging industry, an innovative company has introduced its latest breakthrough product: a Clear Polyester Film Roll. With its unparalleled qualities, this new film has the potential to revolutionize packaging, catering to various industries that rely on robust, eco-friendly, and visually appealing solutions. This article explores the remarkable attributes of this film roll and how it can contribute to the progress of sustainable packaging practices.Unmatched Clarity and Durability:The Clear Polyester Film Roll sets a new standard for clarity, featuring an exceptional transparency that allows the packaging to showcase products seamlessly. Its superior tensile strength ensures durability, providing an effective barrier against punctures and other external factors that could compromise the safety and integrity of the packaged goods. With optimal clarity and durability, this film roll guarantees an unparalleled visual representation and protection of products, enhancing both shelf appeal and customer satisfaction.Sustainability at its Core:Addressing the global concern for environmental sustainability, this Clear Polyester Film Roll offers a significant step towards a greener packaging industry. Unlike traditional films that contain harmful chemicals, this innovative film is manufactured using state-of-the-art technology that eliminates the use of hazardous substances. This environmentally-friendly approach ensures that the film is safe for both customers and the ecosystem, paving the way for a sustainable future.Easy Customization and Application:The Clear Polyester Film Roll allows for easy customization to meet the specific requirements of various industries. Its versatile nature enables it to accommodate different printing techniques, such as flexography, gravure, and digital printing, hence providing ample options for businesses to showcase their brand identity effectively. Additionally, the film’s exceptional roll handling characteristics make it easy to process on high-speed packaging equipment, saving both time and costs in the production process.Unrivaled Barrier Properties:Recognizing the vital need for protective packaging, the Clear Polyester Film Roll exhibits outstanding barrier properties that ensure the preservation of perishable and sensitive goods. From preventing oxygen and moisture ingress to blocking light and maintaining the freshness and quality of the packaged items, this film roll guarantees extended shelf life, reducing potential waste and enhancing overall consumer satisfaction.Applications and Market Potential:The Clear Polyester Film Roll finds versatile applications across numerous sectors, including food and beverages, pharmaceuticals, personal care, and electronics. In the food industry, this film can effectively preserve the flavor, aroma, and nutrient content of perishable items, extending their shelf life and reducing food waste. In the pharmaceutical industry, it offers protection against moisture and UV radiation, ensuring the effectiveness and longevity of medicinal products. Furthermore, the film's high clarity makes it ideal for electronics, where visual appeal is crucial in product packaging.Conclusion:The introduction of the Clear Polyester Film Roll heralds a new era in sustainable and visually appealing packaging solutions. With its unmatched clarity, durability, barrier properties, and commitment to environmental sustainability, this film roll is set to transform the packaging industry. Businesses across various sectors can now incorporate this groundbreaking film into their packaging processes, taking a significant step towards eco-friendly practices while providing customers with exceptional product quality and presentation.

Epoxy Glass Fabric Reinforced with Boron Amine: A Promising Advancement Revealed in Latest News

Title: Revolutionary Epoxy Glass Fabric Boron Amine Emerges as a Game-Changer in Industrial ApplicationsIntroduction:In a breakthrough development, a cutting-edge epoxy glass fabric boron amine composite has been introduced to the market, promising to revolutionize various industrial applications. This remarkable product, developed by [Company], is set to redefine the standards of performance, durability, and versatility in a range of industries. With its unprecedented properties and numerous advantages, this ground-breaking epoxy glass composite is poised to become a game-changer in industrial applications.Body:1. Overview of Epoxy Glass Fabric Boron Amine:Epoxy glass fabric boron amine, a next-generation composite material, represents the fusion of superior quality epoxy resin, glass fabric, and boron amine hardeners. This unique combination results in a highly durable and lightweight material with exceptional strength, thermal stability, and resistance to various environmental factors. The versatility of this composite makes it suitable for a wide range of applications, from aerospace and automotive to construction and electronics industries.2. Unmatched Strength and Durability:The epoxy glass fabric boron amine composite boasts remarkable strength, surpassing traditional composites by a significant margin. Its exceptional mechanical properties, including high tensile strength and stiffness, ensure resistance against harsh environmental conditions such as extreme temperatures, chemicals, and impact. As a result, this composite offers prolonged durability and increased lifespan in various demanding applications.3. Enhanced Thermal Stability:One of the key advantages of epoxy glass fabric boron amine is its outstanding thermal stability. The composite exhibits excellent resistance to extreme temperatures, making it suitable for use in applications where exposure to high or low temperatures is frequent, such as aerospace components or electrical insulation. This remarkable thermal stability enables the composite to maintain its structural integrity and mechanical properties even under challenging operating conditions.4. Corrosion and Chemical Resistance:Epoxy glass fabric boron amine offers exceptional resistance to corrosion and chemicals, making it an ideal choice for applications exposed to aggressive environments. The composite's unique composition provides a protective barrier against corrosive agents, ensuring the integrity and longevity of industrial components. Additionally, this resistance enables a wide range of applications in sectors such as marine, chemical processing, and oil and gas industries.5. Lightweight and Versatile:Despite its unmatched strength and durability, epoxy glass fabric boron amine remains remarkably lightweight. The lightweight characteristic of this composite provides significant advantages, including improved fuel efficiency in transportation applications and ease of handling during manufacturing processes. Furthermore, its versatility allows for customization, shaping, and molding into complex geometries, making it suitable for diverse industries with varying requirements.6. Environmental Sustainability:An important aspect of epoxy glass fabric boron amine lies in its environmental benefits. This composite exhibits low toxicity during manufacturing, resulting in a minimal ecological footprint. Additionally, the composite's durability and longevity contribute to reduced waste and maintenance, thus promoting a more sustainable approach to industrial operations.7. Applications:The superior properties of epoxy glass fabric boron amine make it applicable in a wide range of industries and sectors. Some notable application areas include:- Aerospace: Composite structures, aircraft panels, and components- Automotive: Lightweight body panels, structural parts, and trims- Construction: Reinforced concrete elements, laminates, and coatings- Electronics: Circuit boards, encapsulations, and substrates- Marine: Vessels, hulls, and offshore structures- Chemical Processing: Pipe systems, tanks, and containers- Oil and Gas: Offshore platforms, pipelines, and storage tanksConclusion:With its game-changing properties and extensive applications, epoxy glass fabric boron amine is poised to transform the industrial landscape. This innovative composite, developed by [Company], sets new benchmarks for strength, durability, thermal stability, and versatility. By revolutionizing industries such as aerospace, automotive, construction, electronics, and more, this ground-breaking product is paving the way for a safer, sustainable, and technologically advanced future.

Understanding the Importance of Motor Insulation for Maximum Performance and Safety

[Motor Insulation Company] Revolutionizes Electrical Engineering with Innovative Solutions[date]In an era where technological advancements are reshaping industries daily, [Motor Insulation Company] emerges as a pioneering force, revolutionizing the field of electrical engineering with their innovative motor insulation solutions. With a strong focus on providing cutting-edge products and services, the company is poised to transform the way motors are manufactured, employed, and maintained across various sectors.Established with a vision to overcome the limitations of traditional motor insulation materials, [Motor Insulation Company] has invested significant resources in research and development. Their team of highly skilled engineers and scientists has pushed the boundaries of technology to create an array of groundbreaking solutions that address the ever-evolving demands of the electrical engineering industry.One of the key areas where [Motor Insulation Company] has achieved remarkable success is in the development of advanced insulation materials. By leveraging their expertise in materials science and applying innovative manufacturing processes, the company has introduced a range of cutting-edge insulation products that offer enhanced performance, reliability, and longevity.The flagship product of [Motor Insulation Company], [Product Name], has garnered widespread acclaim for its exceptional characteristics. Combining high dielectric strength with superior thermal conductivity, [Product Name] outperforms traditional insulation materials in terms of efficiency and heat dissipation. This breakthrough allows engineers to design motors that can operate at higher power levels while remaining well-insulated and reliable, thereby optimizing energy consumption and reducing overall operational costs.Beyond their remarkable insulation materials, [Motor Insulation Company] also offers comprehensive support services to ensure their customers maximize the benefits of their products. Their team of technical experts provides consultation, training, and customized solutions, catering to the specific needs of each client. By collaborating closely with customers from various industries, [Motor Insulation Company] has been able to develop application-specific insulation solutions that enhance the performance, longevity, and efficiency of motors in sectors such as automotive, industrial manufacturing, and renewable energy.Moreover, [Motor Insulation Company] prides itself on its commitment to sustainability. In an industry where environmental concerns play an increasingly significant role, the company has taken a proactive approach to reduce the carbon footprint of their operations. By implementing stringent manufacturing processes and using eco-friendly materials, [Motor Insulation Company] ensures that their products not only deliver exceptional performance but also contribute to a greener and more sustainable future.The impact of [Motor Insulation Company]'s innovations goes beyond individual companies; it extends into the broader realm of electrical engineering research. The company actively collaborates with academic institutions and industry partners, fostering a culture of knowledge exchange and driving advancements in the field. By constantly pushing the boundaries of motor insulation technology, [Motor Insulation Company] is forging new frontiers in electrical engineering, inspiring industry-wide improvements and fueling the growth of the global electrical engineering community.Looking ahead, [Motor Insulation Company] remains committed to pushing the boundaries of innovation in the field of motor insulation. They are continuously investing in research and development, driven by the desire to create products that enable more efficient and sustainable electrical systems. With their cutting-edge solutions and unwavering dedication to excellence, [Motor Insulation Company] is poised to shape the future of electrical engineering, revolutionizing the industry and catalyzing a new era of technological advancements.[Word count: 599 words]