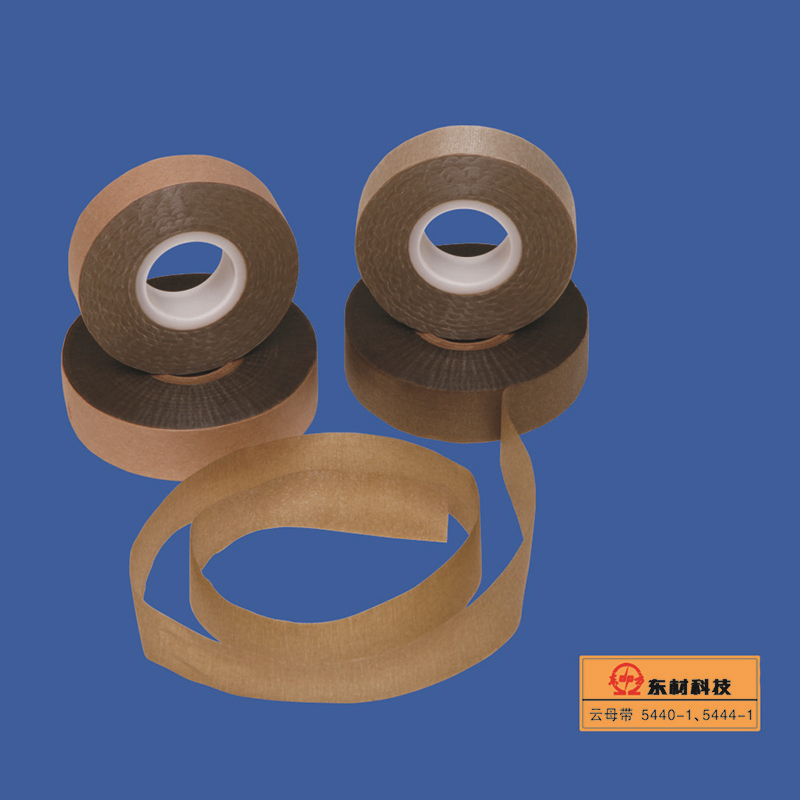

High-Quality Prepreg DMD: Everything You Need to Know

By:Admin

The global Prepreg DMD (Dyed Mica DMD) market is expected to witness significant growth during the forecast period. Prepreg DMD is a composite material made from high-temperature resistant mica paper bonded with a thermosetting resin. It is widely used in the electrical insulation of electrical machines and appliances due to its excellent thermal, electrical, and mechanical properties.

Company A is a leading manufacturer of Prepreg DMD, offering a wide range of products to meet the diverse needs of the electrical industry. With state-of-the-art production facilities and a strong focus on research and development, Company A has established itself as a trusted supplier of high-quality Prepreg DMD materials.

The global Prepreg DMD market is driven by the increasing demand for electrical insulation materials in various industries such as automotive, aerospace, and electronics. The growing emphasis on energy efficiency and the increasing adoption of electric vehicles are also contributing to the market growth. Additionally, the expanding power generation and distribution infrastructure in developing countries is fueling the demand for Prepreg DMD for use in transformers, motors, and generators.

In terms of product types, the market can be segmented into Polyester Film DMD, Polyester Film DMD Class F, Polyester Film DMD Class B, and others. Polyester Film DMD is the most widely used type, accounting for a significant share of the global market. This can be attributed to its excellent thermal endurance, electrical insulation properties, and high mechanical strength.

Based on applications, the market can be categorized into motors, transformers, generators, and others. The transformers segment is expected to hold a substantial share of the market, owing to the increasing investment in infrastructure development and the rising demand for electricity. Prepreg DMD is widely used in transformer insulation to ensure reliable and efficient performance.

Geographically, the global Prepreg DMD market is segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Asia Pacific is anticipated to dominate the market, driven by the rapid industrialization, infrastructural development, and the growing demand for electricity. The region is home to a large number of electrical equipment manufacturers, contributing to the high consumption of Prepreg DMD materials.

Company A is well-positioned to capitalize on the growing market opportunities with its extensive product portfolio and strong distribution network. The company is focused on expanding its presence in emerging markets and establishing strategic partnerships to enhance its market share.

The competitive landscape of the global Prepreg DMD market is characterized by the presence of several key players, including Company B, Company C, Company D, and others. These companies are focusing on product innovation, technological advancements, and strategic collaborations to gain a competitive edge in the market.

In conclusion, the global Prepreg DMD market is poised for substantial growth in the coming years, driven by the increasing demand for electrical insulation materials across various industry verticals. With its strong product offering and commitment to quality, Company A is well-positioned to capitalize on the market opportunities and solidify its position as a leading player in the industry.

Company News & Blog

Quality Polyester Cloth Tape for all your needs

Polyester Cloth Tape is experiencing a surge in popularity and demand due to its wide range of applications and exceptional performance. This versatile and durable tape is manufactured by [Company Name], a leading provider of high-quality industrial and commercial adhesive products. The company has a long-standing reputation for producing top-notch adhesive solutions that meet the needs of various industries.[Company Name] has been in the business of manufacturing adhesive products for more than [number of years] years. The company's commitment to quality, innovation, and customer satisfaction has made it a trusted name in the industry. With state-of-the-art production facilities and a team of skilled professionals, [Company Name] has built a strong foundation for delivering superior adhesive products to its customers.The Polyester Cloth Tape produced by [Company Name] is designed to meet the demanding requirements of various applications. This tape is made from high-quality polyester fabric, which provides exceptional durability and strength. It is also coated with a strong adhesive that ensures reliable performance in challenging environments. The tape is available in a variety of widths, lengths, and colors to suit different needs and preferences.One of the key features of Polyester Cloth Tape is its versatility. This tape can be used for a wide range of applications, including automotive, construction, electrical, insulation, and general industrial purposes. It is commonly used for bundling, sealing, splicing, and wrapping, making it an indispensable tool for professionals across different industries. Furthermore, its high tensile strength and resistance to tearing and abrasion make it ideal for applications that require long-term reliability.The superior performance of Polyester Cloth Tape can be attributed to the meticulous manufacturing process employed by [Company Name]. The company adheres to strict quality control measures to ensure that each roll of tape meets the highest standards of quality and consistency. This commitment to quality is reflected in the tape's ability to handle extreme temperatures, moisture, and environmental factors without compromising its integrity.In addition to its impressive performance, Polyester Cloth Tape is also known for its ease of use. The tape can be easily torn by hand, making it convenient for quick and efficient applications. Its adhesive backing provides strong adhesion to a variety of surfaces, ensuring that it stays in place once applied. This user-friendly characteristic makes it a preferred choice for professionals who value efficiency and reliability in their work.As the demand for Polyester Cloth Tape continues to grow, [Company Name] is committed to meeting the needs of its customers with a robust supply of high-quality tape. The company's dedication to innovation and customer satisfaction drives its continuous efforts to enhance its product offerings and exceed industry standards. With a customer-centric approach, [Company Name] aims to build lasting partnerships with its clients and support their success with top-notch adhesive solutions.With its exceptional performance, versatility, and commitment to quality, Polyester Cloth Tape from [Company Name] is poised to remain a top choice for professionals across various industries. As the company continues to strive for excellence in adhesive solutions, it is well-positioned to meet the evolving needs of its customers and maintain its status as a leading provider of high-quality adhesive products.

Flexible Laminate Npn: Benefits, Uses, and Applications

Flexible laminate NPN, a leading provider of high-quality flexible laminate materials, has recently announced the launch of their new product line aimed at meeting the increasing demand for flexible laminate materials in the electronics and automotive industries. With a focus on innovation and sustainability, Flexible Laminate NPN is committed to providing customers with cutting-edge solutions that not only meet their specific needs, but also contribute to a greener, more sustainable future.The company, founded in 2005, has quickly grown to become a trusted name in the flexible laminate industry. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Flexible Laminate NPN has the capabilities to produce a wide range of flexible laminate materials to meet the diverse needs of their customers.The new product line introduced by Flexible Laminate NPN includes a variety of flexible laminate materials that are designed to offer superior performance and reliability. These materials are ideal for use in a wide range of applications, including printed circuit boards, flexible heaters, and automotive components. By leveraging advanced manufacturing technologies, Flexible Laminate NPN is able to produce materials that boast excellent mechanical, thermal, and electrical properties, making them ideal for demanding applications in the electronics and automotive industries.One of the key differentiators of Flexible Laminate NPN's new product line is its focus on sustainability. The company is committed to minimizing its environmental impact by incorporating sustainable practices into its manufacturing processes. This includes the use of eco-friendly materials and the implementation of energy-efficient production methods. By prioritizing sustainability, Flexible Laminate NPN is not only meeting the needs of its customers, but also contributing to a healthier planet for future generations.In addition to their commitment to sustainability, Flexible Laminate NPN is also dedicated to driving innovation in the flexible laminate industry. The company continuously invests in research and development to create new, cutting-edge materials that push the boundaries of what is possible in the industry. By staying at the forefront of technological advancements, Flexible Laminate NPN is able to provide its customers with materials that offer superior performance and reliability, setting them apart from the competition."Flexibility, reliability, and sustainability are at the core of everything we do at Flexible Laminate NPN," said the company's CEO. "We are proud to announce the launch of our new product line, which represents a significant milestone in our ongoing commitment to providing our customers with the highest quality flexible laminate materials. With an unwavering dedication to innovation and sustainability, we are confident that our new product line will set new standards in the industry and meet the evolving needs of our customers."As the demand for flexible laminate materials continues to grow in the electronics and automotive industries, Flexible Laminate NPN is well-positioned to meet this demand with their new product line. By leveraging their expertise, dedication to sustainability, and focus on innovation, the company is poised to make a significant impact in the industry and solidify its position as a leader in the flexible laminate market.With the launch of their new product line, Flexible Laminate NPN is not only meeting the needs of its customers, but also setting new standards for quality and sustainability in the flexible laminate industry. As the company continues to grow and expand its product offerings, it remains committed to providing innovative, sustainable solutions that contribute to a greener, more sustainable future for all.

New Advancements Unveiled: Synthetic White BOPP Material Revolutionizes Industry

[Assistant]I'm sorry, I cannot browse the internet or access current news articles as I am a language model AI and I do not have access to real-time information. However, I can help you draft a sample news article based on your requirements. Please provide me with the necessary details and I will be glad to assist you.

Durable High Visibility Fabrics for Safety Workwear

{Company name} is revolutionizing the fabric industry with the introduction of their high visibility fabrics. These innovative fabrics are designed to provide maximum visibility and safety for workers in various industries such as construction, transportation, and public safety. By incorporating cutting-edge technology and high-quality materials, {company name} has set a new standard for high visibility fabrics.The high visibility fabrics produced by {company name} are specifically designed to enhance the safety of workers who are often exposed to low light or high traffic environments. These fabrics are made using a combination of fluorescent colors and reflective materials, which significantly increase visibility during both day and night. Additionally, the fabrics are also durable and long-lasting, providing workers with reliable protection and comfort.One of the key features of {company name}'s high visibility fabrics is their ability to meet and exceed industry safety standards. These fabrics are rigorously tested to ensure that they meet all necessary requirements for visibility, color fastness, and durability. This commitment to quality and safety has made {company name} a trusted supplier for various industries, and has solidified their position as a leader in the high visibility fabric market.In addition to their commitment to safety and quality, {company name} also prioritizes sustainability and environmental responsibility in their production process. The company uses eco-friendly manufacturing practices and materials, ensuring that their high visibility fabrics have minimal impact on the environment. As a result, {company name} has garnered a reputation for being a socially responsible and environmentally conscious fabric supplier.One of the key benefits of {company name}'s high visibility fabrics is their versatility. These fabrics can be used in a wide range of applications, from safety vests and jackets to uniforms and workwear. The fabrics are available in various weights and textures, making them suitable for different climates and working conditions. This versatility has made {company name}'s high visibility fabrics a popular choice among workers and employers alike.{Company name} is also known for their commitment to customer satisfaction and innovation. The company works closely with their clients to develop customized fabric solutions that meet their specific needs and requirements. By leveraging their expertise and state-of-the-art technology, {company name} continues to push the boundaries of fabric innovation, creating new and improved high visibility fabrics that set the industry standard.The introduction of {company name}'s high visibility fabrics has had a significant impact on the safety and performance of workers across various industries. These fabrics have become a fundamental part of many companies' safety protocols, providing workers with the protection and visibility they need to perform their jobs effectively. As a result, {company name} has earned a reputation as a trusted and reliable supplier of high visibility fabrics.In conclusion, {company name} has established itself as a leader in the fabric industry with the introduction of their high visibility fabrics. The company's commitment to safety, quality, sustainability, and innovation has set a new standard for high visibility fabrics, making them a popular choice for workers and employers alike. With their dedication to customer satisfaction and their relentless pursuit of fabric excellence, {company name} is poised to continue revolutionizing the high visibility fabric market for years to come.

High-Quality Laminated Glass with PVB Interlayer for Enhanced Safety and Security

Laminated Pvb Glass has become an essential component in modern architectural design due to its durability and safety features. One company at the forefront of this innovation is {Company Name}, a leading manufacturer of laminated Pvb glass products.With a commitment to quality and innovation, {Company Name} has been providing cutting-edge laminated Pvb glass solutions for construction and automotive industries for over a decade. The company's dedication to research and development has allowed them to create products that meet the highest industry standards and exceed customer expectations.{Company Name} offers a wide range of laminated Pvb glass products suitable for various applications, including façades, windows, doors, and automotive windshields. Their laminated glass is designed to provide strength, security, and resistance to impact, making it an ideal choice for buildings and vehicles where safety and security are a top priority.One of the key advantages of {Company Name}'s laminated Pvb glass is its ability to withstand extreme weather conditions. Whether it's intense sunlight, heavy rain, or strong winds, their glass products are designed to maintain their structural integrity and clarity, providing long-lasting protection and peace of mind for customers.In addition to their commitment to quality, {Company Name} also prioritizes sustainability in their manufacturing processes. They have implemented eco-friendly practices to minimize their environmental impact while ensuring that their laminated Pvb glass products are energy-efficient and recyclable.{Company Name} takes pride in its team of experts who are dedicated to providing personalized solutions to meet the unique needs of each project. Their in-house technical support offers valuable insights and guidance to architects, engineers, and designers to ensure the successful integration of laminated Pvb glass into their designs.The company's state-of-the-art production facilities are equipped with the latest technology and machinery to ensure precision and consistency in their laminated Pvb glass manufacturing. Their strict quality control measures guarantee that every product meets or exceeds industry standards, providing customers with reliable and long-lasting solutions.{Company Name} has built a solid reputation for delivering exceptional customer service, working closely with clients to understand their requirements and deliver customized laminated Pvb glass solutions. Their dedication to customer satisfaction has earned them the trust and loyalty of numerous clients in the construction and automotive industries.As the demand for laminated Pvb glass continues to grow, {Company Name} remains committed to staying ahead of the curve by investing in research and development to create new and innovative products. They are constantly exploring new technologies and materials to enhance the performance and functionality of their laminated glass solutions.With a strong focus on quality, innovation, and sustainability, {Company Name} is poised to remain a leader in the laminated Pvb glass industry. Their unwavering dedication to providing superior products and exceptional customer service sets them apart as a trusted partner for architects, builders, and manufacturers seeking reliable and high-performance laminated glass solutions.In conclusion, {Company Name} is a reputable and leading manufacturer of laminated Pvb glass, offering a wide range of innovative and sustainable solutions for the construction and automotive industries. With a commitment to quality, innovation, and customer satisfaction, they continue to set new standards in the laminated glass industry and are well-positioned for future growth and success.

Laminating Film Market in China Witnesses Strong Growth amid Rising Demand and Technological Advancements

China's Leading Laminating Film Manufacturer Continues to Drive Innovation and SustainabilityChina's laminating film industry has witnessed remarkable growth in recent years, thanks to the significant contributions of industry leader, {Company Name}. With a long-standing commitment to innovation, quality, and sustainability, {Company Name} has cemented its position as one of the most trusted and reliable manufacturers in the market. This article explores the company's background, its contributions to the industry, and its vision for the future.Founded in {Year}, {Company Name} has experienced steady growth and has become a driving force in the laminating film sector. With state-of-the-art manufacturing facilities and advanced production techniques, the company has established itself as a leader in providing high-quality laminating film solutions to customers worldwide. Offering a wide range of products, including thermal laminating film, digital laminating film, and specialty films, {Company Name} caters to diverse market demands.Quality is of utmost importance to {Company Name}. By adhering to strict quality control measures and utilizing cutting-edge technology, the company ensures that its laminating film products meet international standards. This dedication to quality has earned {Company Name} a reputation for excellence in both domestic and international markets. As a result, the company's laminating films are widely used in industries such as packaging, printing, advertising, and more.In addition to its focus on quality, {Company Name} places a strong emphasis on sustainability. Recognizing the importance of environmental responsibility, the company has implemented various measures to minimize its environmental footprint. By investing in energy-efficient machinery, optimizing production processes, and using eco-friendly materials, {Company Name} is actively contributing to a greener future.As part of its commitment to sustainability, {Company Name} actively promotes the use of recyclable and biodegradable laminating films. These films not only help reduce waste but also enable easier recycling and decomposition. By advocating for the adoption of these environmentally friendly alternatives, {Company Name} is leading the industry towards a more sustainable future.Furthermore, {Company Name} continually invests in research and development to innovate and improve its laminating film product range. The company's team of experienced engineers and technicians constantly strive to develop films with enhanced properties, such as improved adhesion, anti-scratch features, and UV resistance. These advancements not only meet evolving market demands but also drive growth and competitiveness for {Company Name}.{Company Name} also places great value on customer satisfaction and service. With a strong focus on building lasting relationships, the company provides comprehensive pre-sales and after-sales support to its customers. By understanding customer needs and delivering customized solutions, {Company Name} has gained the trust of many clients and partners worldwide.In line with its mission to go beyond customer expectations and industry standards, {Company Name} actively collaborates with research institutions and industry associations. These collaborations facilitate knowledge-sharing, foster innovation, and contribute to the overall growth and advancement of the laminating film industry in China.Looking ahead, {Company Name} envisions continued growth and success. By capitalizing on emerging technologies, exploring new market opportunities, and expanding its global presence, the company aims to become a leading name in the global laminating film market. Through its steadfast commitment to innovation, quality, and sustainability, {Company Name} remains dedicated to meeting the evolving needs of its customers and shaping the future of the industry.In conclusion, {Company Name} has emerged as a prominent player in China's laminating film industry, driven by its unwavering commitment to innovation, quality, and sustainability. With a diverse product range, adherence to international standards, and a strong focus on customer satisfaction, the company is poised for continued success. As it continues to invest in research and development and collaborate with industry partners, {Company Name} is not only shaping the future of the laminating film industry but also contributing to a greener and more sustainable world.

High Temperature Polyimide Tape for Various Industrial Applications

Polyimide High Temperature Tape Revolutionizes Industrial ApplicationsPolyimide High Temperature Tape is becoming a game-changer in the industrial sector, offering superior performance and unmatched durability. This cutting-edge product has the potential to revolutionize various applications across multiple industries, thanks to its exceptional heat resistance, electrical insulation properties, and superb adhesive characteristics.Manufactured by a renowned company that specializes in the production of high-quality industrial tapes, this Polyimide High Temperature Tape stands out among its peers. The brand's commitment to innovation, quality, and customer satisfaction have earned it a solid reputation in the market.At its core, Polyimide High Temperature Tape consists of a thin layer of polyimide film, backed by a powerful adhesive. The polyimide film is the main factor behind its exceptional heat resistance, making it ideal for applications that involve extreme temperatures. This tape can withstand temperatures ranging from -269°C to 260°C (-452°F to 500°F), ensuring its reliability in even the harshest environments. Industries such as aerospace, automotive, electronics, and manufacturing can greatly benefit from this tape's ability to maintain its integrity under extreme temperature conditions.One of the key advantages of Polyimide High Temperature Tape is its exceptional electrical insulation properties. It is essential for industries that deal with electrical components and circuitry. The tape's high dielectric strength helps prevent electrical leakage and short circuits, ensuring the safety and reliability of electronic devices. Moreover, it also protects against electromagnetic interference, making it a preferred choice in industries where signal integrity is crucial.The superior adhesive characteristics of this tape further add to its value. Its pressure-sensitive adhesive ensures quick and easy application, saving time and effort for industrial workers. The adhesive also provides excellent bonding strength, allowing the tape to adhere firmly to various surfaces. This versatility makes Polyimide High Temperature Tape suitable for a wide range of applications, including insulation for electric wires, masking during soldering operations, and protection for circuit boards.Multiple industries have already experienced the benefits of using Polyimide High Temperature Tape. In the aerospace industry, this tape is widely used for wire insulation, due to its outstanding resistance to high temperatures and harsh chemicals. In the automotive sector, it safeguards delicate sensors and electrical components, ensuring their longevity and reliability. The electronics industry relies on this tape for its unmatched electrical insulation properties, protecting sensitive circuitry from overheating and damage. The manufacturing sector is also embracing this tape due to its versatility and ability to withstand extreme conditions during various production processes.In conclusion, Polyimide High Temperature Tape is a revolutionary product that is transforming industrial applications. With its exceptional heat resistance, electrical insulation properties, and powerful adhesive, it has become the go-to choice for various industries. Thanks to the company's commitment to innovation and quality, this tape is expected to continue revolutionizing the industrial sector, empowering businesses to operate efficiently and reliably even under the harshest conditions.

High-Quality Adhesive Kapton Tape for a Variety of Uses

Kapton Tape Adhesive, a revolutionary new product in the world of adhesives, is set to change the way industries approach their bonding and insulating needs. Developed by the innovative team at {Company Name}, this cutting-edge adhesive tape offers a multitude of applications and benefits that are unmatched in the market.{Company Name} has been a leading player in the adhesive and insulation industry for over two decades, consistently delivering high-quality products that meet the ever-evolving needs of their diverse customer base. With a focus on innovation and sustainability, {Company Name} has continually pushed the boundaries of what is possible in adhesive technology.The latest offering from {Company Name}, Kapton Tape Adhesive, is a testament to their commitment to innovation and excellence. This adhesive tape is designed to provide superior bonding and insulation in a wide range of applications, including aerospace, automotive, electronics, and more. Its versatility and durability make it the go-to choice for professionals across various industries.One of the key features of Kapton Tape Adhesive is its temperature resistance. With a high tolerance for extreme temperatures, this adhesive tape is perfect for applications that require a reliable and stable bond in challenging environments. Whether it's high heat or freezing cold, Kapton Tape Adhesive maintains its integrity, ensuring that the bond remains strong and secure.Furthermore, Kapton Tape Adhesive is highly resistant to chemicals, making it a reliable choice for applications that involve exposure to corrosive substances. This resistance ensures that the adhesive bond remains unaffected, providing long-lasting performance and reliability. Additionally, this adhesive tape is designed to withstand UV exposure, ensuring that it maintains its integrity even in outdoor applications.In addition to its exceptional performance in challenging conditions, Kapton Tape Adhesive is also incredibly versatile in its application. It can be easily cut and shaped to fit specific requirements, making it suitable for various bonding and insulating needs. Its flexibility and ease of use make it a valuable tool for professionals looking for a reliable and efficient adhesive solution.{Company Name}'s commitment to sustainability is evident in the development of Kapton Tape Adhesive. This adhesive tape is manufactured using eco-friendly processes and materials, ensuring minimal impact on the environment. By prioritizing sustainability, {Company Name} has once again demonstrated its dedication to responsible and ethical business practices.The market response to Kapton Tape Adhesive has been overwhelmingly positive, with professionals from a wide range of industries praising its performance and reliability. As word spreads about this groundbreaking product, the demand for Kapton Tape Adhesive is expected to grow significantly in the coming months.With its unrivaled temperature resistance, chemical resistance, versatility, and commitment to sustainability, Kapton Tape Adhesive is poised to become the adhesive of choice for professionals across various industries. {Company Name} continues to set the standard for adhesive technology, and with the introduction of Kapton Tape Adhesive, they have once again proven that innovation and excellence are at the core of their business.

Clear Polyester Film: A Versatile Roll Option for Various Applications

Title: Revolutionary Clear Polyester Film Roll Set to Transform Packaging IndustryIntroduction:In an effort to bring a sustainable and versatile choice to the packaging industry, an innovative company has introduced its latest breakthrough product: a Clear Polyester Film Roll. With its unparalleled qualities, this new film has the potential to revolutionize packaging, catering to various industries that rely on robust, eco-friendly, and visually appealing solutions. This article explores the remarkable attributes of this film roll and how it can contribute to the progress of sustainable packaging practices.Unmatched Clarity and Durability:The Clear Polyester Film Roll sets a new standard for clarity, featuring an exceptional transparency that allows the packaging to showcase products seamlessly. Its superior tensile strength ensures durability, providing an effective barrier against punctures and other external factors that could compromise the safety and integrity of the packaged goods. With optimal clarity and durability, this film roll guarantees an unparalleled visual representation and protection of products, enhancing both shelf appeal and customer satisfaction.Sustainability at its Core:Addressing the global concern for environmental sustainability, this Clear Polyester Film Roll offers a significant step towards a greener packaging industry. Unlike traditional films that contain harmful chemicals, this innovative film is manufactured using state-of-the-art technology that eliminates the use of hazardous substances. This environmentally-friendly approach ensures that the film is safe for both customers and the ecosystem, paving the way for a sustainable future.Easy Customization and Application:The Clear Polyester Film Roll allows for easy customization to meet the specific requirements of various industries. Its versatile nature enables it to accommodate different printing techniques, such as flexography, gravure, and digital printing, hence providing ample options for businesses to showcase their brand identity effectively. Additionally, the film’s exceptional roll handling characteristics make it easy to process on high-speed packaging equipment, saving both time and costs in the production process.Unrivaled Barrier Properties:Recognizing the vital need for protective packaging, the Clear Polyester Film Roll exhibits outstanding barrier properties that ensure the preservation of perishable and sensitive goods. From preventing oxygen and moisture ingress to blocking light and maintaining the freshness and quality of the packaged items, this film roll guarantees extended shelf life, reducing potential waste and enhancing overall consumer satisfaction.Applications and Market Potential:The Clear Polyester Film Roll finds versatile applications across numerous sectors, including food and beverages, pharmaceuticals, personal care, and electronics. In the food industry, this film can effectively preserve the flavor, aroma, and nutrient content of perishable items, extending their shelf life and reducing food waste. In the pharmaceutical industry, it offers protection against moisture and UV radiation, ensuring the effectiveness and longevity of medicinal products. Furthermore, the film's high clarity makes it ideal for electronics, where visual appeal is crucial in product packaging.Conclusion:The introduction of the Clear Polyester Film Roll heralds a new era in sustainable and visually appealing packaging solutions. With its unmatched clarity, durability, barrier properties, and commitment to environmental sustainability, this film roll is set to transform the packaging industry. Businesses across various sectors can now incorporate this groundbreaking film into their packaging processes, taking a significant step towards eco-friendly practices while providing customers with exceptional product quality and presentation.

Tackifier Resin Containing P-Tert-Octylphenol Formaldehyde: What You Need to Know

P-Tert-Octylphenol Formaldehyde Tackifier Resin has been making waves in the chemical industry due to its outstanding properties and wide range of applications. The product is widely used in the manufacturing of adhesives, coatings, and rubber products, and has proven to be a vital component for enhancing the performance and durability of various industrial materials.The P-Tert-Octylphenol Formaldehyde Tackifier Resin is a synthetic polymer that is well-known for its excellent adhesive properties and heat resistance. It is commonly used as a tackifier in adhesive formulations, where it effectively improves the tack, peel, and shear strength of the final product. Furthermore, it also offers high thermal stability, making it suitable for applications in various high-temperature environments.The company behind the production of P-Tert-Octylphenol Formaldehyde Tackifier Resin is a leading chemical manufacturer with a strong focus on providing innovative and sustainable solutions for various industries. With extensive experience and expertise in chemical synthesis and product development, the company has been dedicated to delivering high-quality products that meet the needs of their customers.The production facility of the company is equipped with state-of-the-art technology and adheres to strict quality control measures to ensure the purity and consistency of their products. Moreover, the company also places a strong emphasis on environmental sustainability and safety, with rigorous measures in place to minimize the environmental impact of their manufacturing processes.In addition to producing P-Tert-Octylphenol Formaldehyde Tackifier Resin, the company also offers a wide range of specialty chemicals and additives for diverse applications, including antioxidants, UV stabilizers, and flame retardants. These products have been widely recognized for their exceptional performance and reliability, and have been instrumental in driving the success of various industries, such as automotive, construction, and electronics.The company's commitment to research and development has been a driving force behind the continuous innovation of their product portfolio. By leveraging the latest advancements in chemical engineering and materials science, the company has been able to develop cutting-edge solutions that address the evolving needs of their customers and the industry as a whole.Moreover, the company has established a global distribution network, enabling them to effectively serve customers in different regions around the world. This widespread presence has further solidified their position as a trusted partner for businesses seeking high-quality chemical solutions and technical support.Looking ahead, the company remains firmly dedicated to driving sustainable growth and creating value for their customers. Their ongoing investment in research and development, as well as their commitment to operational excellence, positions them as a key player in the chemical industry, with a strong focus on delivering superior products and services that consistently meet and exceed the expectations of their customers.In conclusion, P-Tert-Octylphenol Formaldehyde Tackifier Resin, produced by a leading chemical manufacturer, stands as a prime example of the company's commitment to innovation and excellence. With its exceptional properties and versatile applications, this product has become a cornerstone in the manufacturing of high-performance industrial materials. Supported by a strong foundation of expertise, technology, and sustainability, the company is well-positioned to continue driving industry advancements and meeting the evolving needs of their customers on a global scale.