Ultimate Guide to Bpf Type Benzoxazine Resin: Uses, Properties, and Applications

By:Admin

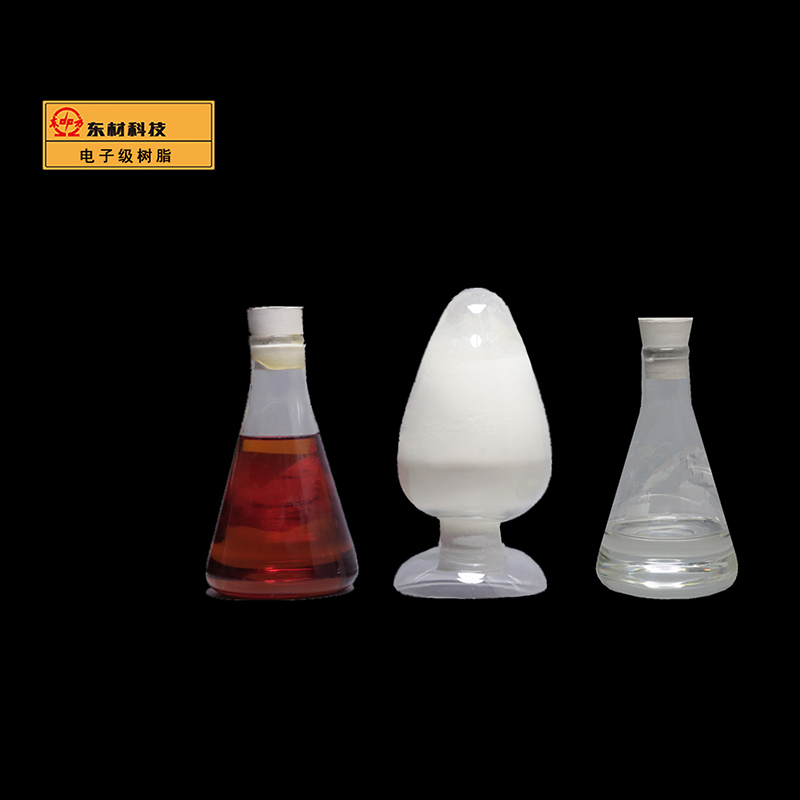

In the ever-evolving world of composite materials, the introduction of Bpf Type Benzoxazine Resin has been nothing short of a game-changer. Developed by a leading company in the industry, this innovative resin is set to revolutionize the way composite materials are manufactured and used.

Benzoxazine resins have been gaining attention in recent years for their exceptional thermal and mechanical properties. With high glass transition temperatures, low curing shrinkage, and excellent flame resistance, benzoxazine resins have found applications in a wide range of industries, including aerospace, automotive, electronics, and construction.

The Bpf Type Benzoxazine Resin takes these exceptional properties to a whole new level. With its unique formulation, this resin offers superior toughness, enhanced heat resistance, and improved processability. These advancements make it an ideal choice for demanding applications that require high performance and reliability.

One of the key advantages of the Bpf Type Benzoxazine Resin is its ability to meet the growing demand for lightweight and high-strength materials. As industries seek to reduce fuel consumption, improve energy efficiency, and enhance overall performance, the need for advanced composites has never been greater. The Bpf Type Benzoxazine Resin addresses this need by offering a combination of strength, stiffness, and durability that is unmatched by traditional materials.

Moreover, the exceptional thermal stability of the Bpf Type Benzoxazine Resin makes it an ideal candidate for applications in high-temperature environments. Whether it's in the harsh conditions of outer space or the extreme temperatures of industrial processes, this resin is capable of maintaining its properties and performance, ensuring the reliability and longevity of the final product.

In addition to its superior performance, the Bpf Type Benzoxazine Resin also offers benefits in terms of processing and manufacturing. Its low viscosity and long pot life provide manufacturers with greater flexibility and control during the production process. This, in turn, can lead to cost savings and efficiency gains, making the resin an attractive option for businesses looking to improve their bottom line.

The company behind the development of the Bpf Type Benzoxazine Resin has a long-standing reputation for delivering high-quality materials and solutions to the composite materials industry. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in the field of advanced materials.

For over a decade, the company has invested significant resources into the development of benzoxazine resins, and the Bpf Type Benzoxazine Resin is the culmination of these efforts. Leveraging its expertise in polymer chemistry and materials science, the company has engineered a resin that not only meets but exceeds the stringent requirements of modern composite applications.

Looking ahead, the company is committed to further advancing the capabilities of benzoxazine resins and exploring new possibilities for their use. As the demand for high-performance, sustainable materials continues to grow, the company sees great potential for benzoxazine resins to play a key role in shaping the future of various industries.

In conclusion, the introduction of the Bpf Type Benzoxazine Resin marks a significant milestone in the composite materials industry. With its exceptional properties, versatile applications, and potential for innovation, this resin is set to redefine the possibilities of what can be achieved with composite materials. As industries continue to seek ways to improve performance, efficiency, and sustainability, the Bpf Type Benzoxazine Resin stands ready to meet these challenges and usher in a new era of advanced composites.

Company News & Blog

New Optical Film for Polarizer Releasing Film Released

Global leader in the manufacturing of advanced optical pet base film for polarizer releasing film, (Brand Name), has announced the release of its latest innovative product. The company, with a steadfast commitment to excellence and technological innovation, has developed a cutting-edge pet base film that is set to revolutionize the industry.The newly released pet base film is designed to enhance the performance of polarizer films, which are widely used in electronic displays such as LCDs, OLEDs, and touch panels. As the demand for high-quality displays continues to grow, manufacturers are in search of advanced materials that can improve the overall performance and durability of their products. (Brand Name)’s optical pet base film is poised to meet this demand with its superior quality and performance.The optical pet base film is engineered to provide exceptional optical clarity, high light transmission, and superior durability. By incorporating state-of-the-art technology and precision manufacturing processes, (Brand Name) has created a product that meets the stringent requirements of modern display applications. The film’s high transparency and low haze properties ensure that it does not compromise the visual quality of the display, making it an ideal choice for high-resolution screens.Moreover, the pet base film offers excellent mechanical properties, including high tensile strength and dimensional stability. This ensures that the film can withstand the rigors of manufacturing processes and maintain its integrity throughout the lifecycle of the display. Additionally, the film is designed to be compatible with various coating and lamination processes, enabling manufacturers to seamlessly integrate it into their production lines.(Brand Name)’s commitment to sustainability is also evident in the manufacturing of the optical pet base film. The company employs eco-friendly processes and materials, minimizing its environmental impact while delivering a product that meets the highest industry standards. As environmental consciousness continues to be a priority for businesses and consumers alike, (Brand Name)’s sustainable approach sets it apart as a responsible industry leader.With the release of its advanced pet base film, (Brand Name) reinforces its position as a leading provider of high-performance materials for the display industry. The company’s dedication to research and development has enabled it to stay at the forefront of technological advancements, delivering products that address the evolving needs of the market. (Brand Name)’s optical pet base film is poised to set a new standard for performance and quality in the polarizer releasing film segment.As a globally recognized manufacturer, (Brand Name) serves a diverse customer base, including major players in the electronics and display industries. The company’s products are trusted for their reliability, performance, and quality, making it the preferred choice for manufacturers seeking cutting-edge materials for their products. With a strong global presence and a commitment to customer satisfaction, (Brand Name) is well-positioned to support the growing demand for advanced pet base film solutions.In conclusion, the release of (Brand Name)’s optical pet base film marks a significant milestone for the company and the display industry as a whole. With its commitment to technological innovation, sustainability, and customer satisfaction, (Brand Name) continues to drive the advancement of high-performance materials for electronic displays. The newly released pet base film is a testament to the company’s dedication to excellence, and it is poised to make a lasting impact on the market. As the demand for superior display solutions continues to grow, (Brand Name) stands ready to lead the way with its innovative and high-quality products.

Durable Phenolic Resin: A Versatile Material for Various Applications

[Company Introduction] Established in 1998, our company has been a leading manufacturer and supplier of high-quality chemicals and resins for various industries. With a commitment to innovation and customer satisfaction, we have developed a strong reputation for delivering exceptional products and services to our clients worldwide. Our state-of-the-art facilities and dedicated team of experts enable us to consistently produce top-notch chemical products that meet the stringent quality standards of today’s market.[News Content]Phenolic Resin: A Breakthrough in Chemical TechnologyIn the world of chemical manufacturing, innovation is key to staying ahead of the competition and meeting the ever-evolving demands of different industries. Our company is proud to announce the development of a groundbreaking product that is set to revolutionize the field of chemical engineering – Phenolic Resin.Phenolic resin is a type of synthetic polymer that is widely used in the production of various industrial and consumer goods. It is known for its exceptional heat resistance, high mechanical strength, and resistance to chemicals and solvents. With these remarkable properties, phenolic resin has become an indispensable material in industries such as automotive, construction, electrical, and consumer goods manufacturing.What sets our phenolic resin apart from the rest is the advanced formulation and manufacturing process that we have implemented. By leveraging our extensive expertise in chemical engineering and state-of-the-art production facilities, we have been able to create a phenolic resin that surpasses the performance and quality standards of existing products in the market.One of the key features of our phenolic resin is its superior heat resistance, making it an ideal material for applications that require reliable performance in high-temperature environments. This includes the production of automotive components, electrical insulation materials, and industrial machinery parts that are subjected to extreme heat and thermal stress.Furthermore, our phenolic resin offers exceptional mechanical strength, providing durability and reliability in a wide range of applications. From load-bearing structural components in construction to impact-resistant consumer goods, our phenolic resin delivers outstanding performance under demanding conditions.In addition to its physical properties, our phenolic resin also offers excellent resistance to chemicals and solvents, making it a versatile material for various industrial processes. This makes it an excellent choice for manufacturing components that are exposed to corrosive substances or harsh environmental conditions.With the introduction of our advanced phenolic resin, our company aims to provide our clients with a superior solution for their chemical and material needs. We are confident that our phenolic resin will set a new standard for performance and quality in the industry, and we are excited to see the positive impact it will have on our customers’ products and processes.As we continue our commitment to innovation and excellence, our company remains dedicated to pushing the boundaries of chemical technology and delivering value to our clients. With the launch of our phenolic resin, we are taking a significant step forward in our mission to provide cutting-edge solutions that drive success and growth for our customers across the globe.In conclusion, our company’s introduction of advanced phenolic resin is a testament to our ongoing commitment to innovation, quality, and customer satisfaction. With our expertise and resources, we are confident that our phenolic resin will not only meet but exceed the expectations of our clients and contribute to the advancement of various industries. We are excited to bring this revolutionary product to the market and look forward to the positive impact it will have on the chemical engineering landscape.

Top Dry Film for Effective Coating and Protection

Dry Film is a reputable company that specializes in the production of high-quality dry film products for various industrial applications. The company has been a leading innovator in the industry, providing customers with reliable and cost-effective solutions for their manufacturing needs. With a strong focus on research and development, Dry Film has been able to stay ahead of the competition and consistently deliver cutting-edge products to its customers.The company's dry film products are widely used in the electronics, automotive, aerospace, and medical industries, among others. These industries rely on Dry Film's products to ensure the smooth and efficient operation of their manufacturing processes. The company's commitment to quality and customer satisfaction has made it a trusted partner for many businesses around the world.Recently, Dry Film introduced a new line of dry film products that have been designed to offer even greater performance and reliability. These new products have been carefully developed using the latest technology and manufacturing techniques, ensuring that they meet the highest standards of quality and consistency. With this new line of products, customers can expect improved efficiency and productivity in their operations.One of the key features of Dry Film's new products is their enhanced durability and resistance to wear and tear. This makes them ideal for use in high-stress environments where traditional film products may not hold up. The new products also offer improved adhesion properties, ensuring that they stay in place even under the toughest conditions. This makes them a reliable choice for a wide range of applications, from circuit board production to automotive manufacturing.In addition to their performance benefits, Dry Film's new products also offer environmental advantages. The company has taken steps to ensure that its manufacturing processes are as sustainable as possible, reducing waste and minimizing its impact on the environment. This commitment to sustainability is reflected in the new line of products, which have been designed with eco-friendly materials and production methods.With the introduction of these new products, Dry Film is once again demonstrating its dedication to innovation and excellence. The company's ongoing investment in research and development is a testament to its commitment to staying at the forefront of the industry. Customers can trust that they are getting the very best products when they choose Dry Film for their dry film needs.As the demand for high-quality dry film products continues to grow, Dry Film is well-positioned to meet the needs of its customers. With its extensive experience and expertise in the industry, the company is prepared to take on new challenges and continue to provide innovative solutions for its customers. Whether it's in the electronics, automotive, aerospace, or medical industries, businesses can rely on Dry Film to deliver the products they need to succeed.With its focus on quality, reliability, and sustainability, Dry Film is a company that customers can trust. The introduction of the new line of products is just the latest example of the company's ongoing commitment to excellence. As the industry continues to evolve, Dry Film will be there, leading the way with innovative products that meet the needs of its customers.

Essential Guide to Drywall Joint Tape: Everything You Need to Know

The drywall joint tape is one of the essential materials used in construction projects, and it plays a significant role in keeping the joints of the drywall secure and durable. It provides a smooth and seamless finish to the walls, ensuring that the construction project is of the highest quality. One of the leading manufacturers of drywall joint tape is {remove brand name}, a company that has been at the forefront of producing high-quality construction materials for over two decades.{Remove brand name} is a company known for its commitment to excellence and innovation in the construction industry. With a strong emphasis on research and development, the company has been able to introduce cutting-edge products that have revolutionized the way construction projects are carried out. The company has a state-of-the-art manufacturing facility that is equipped with the latest technology and machinery, allowing them to produce top-notch construction materials that meet the highest standards.The drywall joint tape produced by {remove brand name} is crafted with precision and attention to detail, ensuring that it provides the necessary support and reinforcement to the drywall joints. The tape is made from high-quality materials that are resistant to tearing and stretching, making it ideal for use in both residential and commercial construction projects. The adhesive used in the tape is strong, yet flexible, allowing for easy application and ensuring a secure bond with the drywall.One of the key features of the drywall joint tape from {remove brand name} is its versatility and ease of use. The tape is designed to be compatible with a variety of joint compounds, making it suitable for a wide range of construction applications. Whether it's for taping the seams of newly installed drywall or repairing cracks and holes in existing walls, the joint tape from {remove brand name} is the go-to choice for contractors and construction professionals.In addition to its superior quality, the drywall joint tape from {remove brand name} also offers excellent value for money. The company is committed to providing construction materials that are not only of the highest quality but also affordable and cost-effective. This commitment to offering competitive pricing has made {remove brand name} a trusted and preferred supplier of construction materials by builders and contractors.Another aspect that sets {remove brand name} apart from its competitors is its dedication to sustainability and environmental responsibility. The company places a strong emphasis on using eco-friendly materials and manufacturing processes, ensuring that their products have minimal impact on the environment. This commitment to sustainability has not only earned {remove brand name} a reputation as a responsible and ethical company but has also contributed to the development of eco-friendly construction practices in the industry.Overall, the drywall joint tape from {remove brand name} is a testament to the company's unwavering dedication to quality, innovation, and environmental responsibility. As the construction industry continues to evolve, {remove brand name} remains at the forefront, consistently offering products that exceed the expectations of their customers. From its state-of-the-art manufacturing facility to its commitment to sustainability, {remove brand name} is a company that continues to set the standard for excellence in the construction materials industry.

High-quality Functionnal Coating Material for Various Applications

Introducing a Revolutionary Functional Coating Material: A Breakthrough TechnologyIn the ever-evolving world of technology and innovation, a company called {} has made a significant breakthrough with their revolutionary functional coating material. This cutting-edge product is set to introduce a new era of protection and performance in various industries, including automotive, aerospace, and electronics.{} is a leading provider of advanced materials and solutions for a wide range of industries. With a strong focus on research and development, {} has been at the forefront of innovation, consistently delivering high-quality products to meet the evolving needs of their customers.The functional coating material developed by {} is a game-changer in the industry. It offers a unique combination of properties that provide exceptional protection, durability, and performance. This material is designed to enhance the functionality and longevity of various surfaces, including metals, plastics, and composites. It provides resistance to corrosion, abrasion, and wear, making it an ideal solution for challenging environments.One of the key features of this functional coating material is its versatility. It can be applied to a wide range of substrates, making it suitable for various applications. Whether it's protecting the body of a car from harsh weather conditions, ensuring the longevity of critical components in aerospace applications, or improving the performance of electronic devices, this material is designed to deliver exceptional results.Furthermore, {}'s commitment to sustainability is evident in the development of this functional coating material. It is engineered to be environmentally friendly, with a focus on reducing waste and minimizing the impact on the environment. This aligns with {}'s dedication to corporate social responsibility and their efforts to create a more sustainable future for the planet.The introduction of this functional coating material is poised to have a significant impact on various industries. With its enhanced protection and performance properties, it has the potential to revolutionize the way surfaces are treated and protected. This could result in improved efficiency, reduced maintenance costs, and extended service life for a wide range of applications.The automotive industry is one of the key sectors that could benefit from this breakthrough technology. With the ever-increasing demand for more durable and long-lasting coatings, this material offers a promising solution to enhance the performance and longevity of vehicle surfaces. It could also contribute to the development of more sustainable and eco-friendly automotive coatings, aligning with the industry's push towards greener technologies.In the aerospace industry, where durability and performance are critical, this functional coating material could offer a significant advantage. With its resistance to corrosion and wear, it has the potential to protect critical components and structures, ensuring the safety and reliability of aircraft and spacecraft. This could translate to cost savings and improved operational efficiency for aerospace manufacturers and operators.In the electronics industry, the demand for high-performance coatings continues to grow as devices become more advanced and compact. This functional coating material could offer a solution to enhance the reliability and longevity of electronic components, leading to improved performance and reduced maintenance requirements for electronic devices.With its unique combination of properties and its potential to revolutionize various industries, {}'s functional coating material is set to make a lasting impact in the market. As a company at the forefront of innovation, {}'s commitment to research and development has once again resulted in a groundbreaking technology that has the potential to redefine the way surfaces are protected and enhanced.In conclusion, the introduction of {}'s functional coating material represents a significant milestone in the industry. With its exceptional properties and potential for widespread applications, it has the power to transform the way surfaces are treated and protected across various sectors. As a leading provider of advanced materials and solutions, {} continues to demonstrate its dedication to innovation and sustainability, paving the way for a more advanced and sustainable future.

New Anti-Dripping Fabric for Polyester Material

Anti-Dripping FR Polyester: A Revolutionary Innovation in Fire SafetyIn a world where fire safety is of utmost importance, the development of innovative materials that can withstand high temperatures and reduce the spread of fire is crucial. One such groundbreaking material is Anti-Dripping FR Polyester, which has been proven to be highly effective in preventing the spread of fire and protecting lives and property.{The company}, a leading manufacturer of advanced textiles and materials, is at the forefront of this revolutionary innovation. With a strong commitment to research and development, {the company} has been able to create Anti-Dripping FR Polyester, a material that is set to revolutionize the way we approach fire safety.Anti-Dripping FR Polyester is a polyester fabric that has been specifically designed to resist dripping when exposed to fire. This unique feature is critical in preventing the spread of fire, as dripping materials can cause the fire to spread rapidly and can pose a significant risk to individuals and property.Furthermore, Anti-Dripping FR Polyester has been rigorously tested to ensure that it meets the highest standards of fire safety. The material has been certified to be flame retardant, meaning that it does not support combustion and will not contribute to the spread of fire. This makes it an ideal choice for a wide range of applications, including upholstery, curtains, and other interior textiles, where fire safety is of paramount importance.In addition to its exceptional fire-resistant properties, Anti-Dripping FR Polyester also offers a range of other benefits. It is highly durable and long-lasting, making it suitable for use in high-traffic and demanding environments. The material is also resistant to UV rays and does not degrade over time, ensuring that it maintains its fire-resistant properties for an extended period.{The company} has been able to achieve these remarkable advancements in fire safety through its state-of-the-art manufacturing processes and commitment to quality. The company’s production facilities are equipped with the latest technology, allowing for the creation of high-performance materials that meet the most stringent standards.With an extensive research and development team, {the company} continues to push the boundaries of what is possible in the field of fire safety. The company is dedicated to staying ahead of the curve and is constantly looking for new ways to improve the performance and capabilities of its materials.Moreover, {the company} is committed to sustainability and environmental responsibility. The production of Anti-Dripping FR Polyester is carried out in a manner that minimizes its impact on the environment, ensuring that it aligns with the company’s principles of corporate social responsibility.The launch of Anti-Dripping FR Polyester marks a significant milestone in the field of fire safety. With its exceptional fire-resistant properties and long-lasting durability, this material is set to make a positive impact on a wide range of industries, from construction and interior design to automotive and transportation.In conclusion, {the company} has once again demonstrated its leadership in the development of innovative materials with the introduction of Anti-Dripping FR Polyester. As the demand for fire-resistant materials continues to grow, {the company} remains at the forefront of this critical industry, providing solutions that not only meet but exceed the highest standards of fire safety.

Epoxy Resin Containing Bisphenol A Found to Be Harmful - Experts Express Concerns

Title: Bisphenol A Epoxy Resin: A Revolutionary Addition to the Manufacturing IndustryIntroduction:Established in [year], [Company Name] has paved its way to become a leading innovator in the field of chemical solutions. Renowned for its commitment to quality and excellence, the company has recently introduced an advanced range of Bisphenol A Epoxy Resin, which is expected to revolutionize the manufacturing industry.[Company Name] has been at the forefront of designing cutting-edge solutions that cater to various sectors such as automotive, electronics, construction, and more. With an emphasis on technological advancements and sustainability, the company aims to provide high-performance materials while minimizing the environmental impact. The introduction of Bisphenol A Epoxy Resin aligns perfectly with the organization's vision and commitment.Bisphenol A Epoxy Resin - An Overview:Bisphenol A Epoxy Resin is a robust, versatile, and sustainable material that has gained significant attention in recent years. It is a thermosetting polymer formed by the reaction of Bisphenol A and Epichlorohydrin. Known for its exceptional mechanical properties, electrical insulation properties, and resistance to heat and chemicals, this resin has a plethora of applications across different industries.Key Features and Benefits:1. Superior Mechanical Strength: Bisphenol A Epoxy Resin exhibits exceptional mechanical properties, including high tensile strength and resistance to impact, making it an ideal choice for structural applications.2. Electrical Insulation Properties: The resin demonstrates excellent electrical insulation capabilities, ensuring reliable and safe performance in electrical and electronic devices, such as circuit boards, connectors, and insulators.3. Chemical and Heat Resistance: The inherent chemical resistance of the resin makes it suitable for a wide range of applications involving exposure to harsh chemicals, acids, and solvents. Additionally, its resistance to high temperatures allows it to be used in heat-resistant coatings, adhesives, and composites.4. Environmental Sustainability: [Company Name]'s Bisphenol A Epoxy Resin is manufactured using environmentally friendly processes, adhering to stringent quality control measures. Its recyclable nature further supports the organization's commitment to sustainability.Applications:1. Automotive Industry: The exceptional mechanical strength and heat resistance of Bisphenol A Epoxy Resin make it an ideal material for automotive parts, such as bumpers, body panels, and engine components, providing enhanced durability and lightweight solutions.2. Electronics and Electrical Sector: The resin's excellent electrical insulation properties make it a top choice for manufacturing circuit boards, connectors, potting materials, insulators, and encapsulation of electronic components.3. Construction and Infrastructure: Bisphenol A Epoxy Resin finds applications in the construction industry as a coating material for concrete surfaces, providing protection against chemical corrosion and enhancing the lifespan of structures.4. Aerospace and Defense: The resin's ability to withstand extreme temperatures and its superior mechanical strength make it suitable for use in aerospace and defense applications, including aircraft components, military equipment, and composite materials.Conclusion:The introduction of [Company Name]'s Bisphenol A Epoxy Resin marks a significant milestone in the manufacturing industry. With its exceptional mechanical, electrical, and chemical resistance properties, this versatile material offers a wide range of applications across various sectors. Furthermore, the company's commitment to sustainability ensures that the production of this resin aligns with the growing demand for environmentally friendly solutions. As [Company Name] continues to innovate, the future of manufacturing looks promising with Bisphenol A Epoxy Resin leading the way in revolutionizing industries worldwide.

Durable and Versatile Polyester Film for a Variety of Applications

Clear Polyester Film is a revolutionary product that has gained popularity in various industries due to its exceptional properties and versatility. It is a high-performance film that is known for its excellent transparency, tensile strength, and dimensional stability. The clear polyester film is commonly used in a wide range of applications, including packaging, electrical insulation, and lamination.One of the leading manufacturers of clear polyester film is **{Company Name}**. The company has been a pioneer in the production of high-quality polyester film for over a decade. Their clear polyester film is manufactured using advanced technology and high-quality raw materials, ensuring superior performance and reliability. With a strong focus on innovation and customer satisfaction, **{Company Name}** has become a trusted name in the industry.The clear polyester film offered by **{Company Name}** is renowned for its exceptional clarity and durability. It is designed to provide optimum protection and preservation for various products, making it ideal for use in packaging applications. The film also offers excellent chemical resistance, making it suitable for harsh environmental conditions.In addition to packaging, clear polyester film is widely used for electrical insulation purposes. Its high dielectric strength and thermal stability make it an ideal choice for insulating electrical components and wires. **{Company Name}**'s clear polyester film meets the stringent requirements for electrical insulation, making it a preferred choice for manufacturers in the electronics and electrical industries.Furthermore, the clear polyester film is also used for lamination purposes, where it provides a protective and glossy finish to printed materials. Its smooth surface and excellent adhesion properties ensure a high-quality finish, making it a popular choice for lamination applications in the printing and graphic arts industry.The versatility of clear polyester film makes it a preferred choice for various other applications, including photovoltaic modules, medical packaging, and industrial applications. Its ability to withstand high temperatures and harsh environments makes it suitable for a wide range of demanding applications.**{Company Name}** is committed to delivering top-quality clear polyester film that meets the diverse needs of its customers. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that the film meets the highest standards of performance and reliability. With a focus on sustainability, **{Company Name}** also places a strong emphasis on environmental responsibility in its production processes.As a customer-centric company, **{Company Name}** offers customized solutions to meet the specific requirements of its clients. Whether it is for packaging, electrical insulation, lamination, or any other application, **{Company Name}** works closely with its customers to provide tailored solutions that meet their unique needs.In conclusion, clear polyester film is a versatile and high-performance product that finds extensive applications across various industries. **{Company Name}**'s commitment to quality and innovation has made it a leading manufacturer of clear polyester film, providing customers with reliable and high-quality solutions for their diverse needs. With a focus on technological advancement and customer satisfaction, **{Company Name}** continues to set industry standards for clear polyester film, delivering exceptional products that meet the evolving demands of the market.

Polyester Yarn and Low Shrinkage Prices in China: Latest Updates

China's polyester yarn and low shrinkage price has seen a significant increase in the recent months, due to various market factors. The rise in price has had an impact on the textile industry, with companies having to adjust their production and pricing strategies to cope with the changes.The increase in price of polyester yarn and low shrinkage can be attributed to a number of factors. One of the major reasons for the rise in price is the increase in the cost of raw materials. The cost of crude oil, which is a key raw material used in the production of polyester yarn, has been steadily increasing. This has led to an increase in the cost of production for manufacturers, and in turn, an increase in the price of the final product.Another factor contributing to the increase in price is the high demand for polyester yarn and low shrinkage in the market. The textile industry has been experiencing a surge in demand for these products, driven by the growing popularity of synthetic fibers in the production of textiles and garments. This high demand has put pressure on manufacturers to increase production, leading to a shortage of supply and subsequently an increase in price.In addition to these factors, the ongoing trade tensions between China and other major economies have also had an impact on the price of polyester yarn and low shrinkage. The imposition of tariffs and trade restrictions have disrupted the supply chain, leading to an increase in the cost of production and a subsequent increase in price.The rise in price of polyester yarn and low shrinkage has had a significant impact on the textile industry. Many companies have had to adjust their production and pricing strategies in response to the increased cost. Some have had to increase the price of their products, while others have had to find ways to cut costs in order to maintain their competitive edge in the market.One company that has been impacted by the increase in price is {}. [Company] is a leading manufacturer of polyester yarn and low shrinkage. The company has been producing high-quality products for the textile industry for many years, and has built a strong reputation for reliability and innovation.The increase in price of polyester yarn and low shrinkage has posed a challenge for [Company]. The company has had to reassess its production and pricing strategies in order to cope with the changes in the market. One of the steps it has taken is to streamline its production process in order to reduce costs. By optimizing its production process, the company has been able to mitigate some of the impact of the increase in price.Additionally, [Company] has been working closely with its suppliers to find ways to minimize the impact of the increase in the cost of raw materials. By renegotiating contracts and exploring alternative sourcing options, the company has been able to keep the cost of production in check.Furthermore, [Company] has also been focusing on product innovation in order to maintain its competitive edge in the market. The company has been investing in research and development to create new and improved products that offer better value to its customers. By offering innovative products, the company has been able to justify the increase in price and maintain its position as a leader in the market.Despite the challenges posed by the increase in price of polyester yarn and low shrinkage, [Company] remains optimistic about the future. The company is confident that its proactive approach to the changing market dynamics will enable it to weather the storm and emerge stronger. With its commitment to innovation and customer satisfaction, [Company] is well positioned to continue to thrive in the competitive textile industry.In conclusion, the increase in price of polyester yarn and low shrinkage in China has posed a significant challenge for the textile industry. Companies have had to adjust their production and pricing strategies in response to the changes in the market. Despite these challenges, companies like [Company] have been able to adapt and remain resilient, thanks to their proactive approach and commitment to innovation. As the market continues to evolve, it is essential for companies to remain agile and adaptable in order to maintain their competitive edge.

Benefits and Uses of Metallized Polypropylene Film in Packaging and Industrial Applications

Metallized Polypropylene Film is a revolutionary product that has gained wide popularity in various industries due to its excellent performance and durability. This film is manufactured by {}, a leading company specializing in the production of high-quality packaging materials and films.{} was established in 1995 and has since emerged as a pioneering force in the packaging industry. The company's state-of-the-art manufacturing facility is equipped with advanced machinery and technology, allowing them to produce top-notch products that meet the highest quality standards.Metallized Polypropylene Film is one of the flagship products offered by {}. It is a versatile packaging material that is widely used in the food and beverage industry, pharmaceuticals, electronics, and many other sectors. The film is known for its exceptional strength, moisture resistance, and high oxygen barrier properties, making it ideal for preserving the freshness and quality of a wide range of products.One of the key features of Metallized Polypropylene Film is its metallized layer, which provides superior barrier properties against moisture, gases, and odors. This barrier helps protect the packaged products from external elements, ensuring their longevity and quality. In addition, the film is also heat sealable, allowing for easy and convenient packaging of various products.Furthermore, Metallized Polypropylene Film is environmentally friendly and recyclable, making it an ideal choice for companies looking to reduce their carbon footprint and embrace sustainable packaging solutions. This aligns with the company's commitment to minimizing its impact on the environment and promoting eco-friendly practices in the industry.The quality and performance of Metallized Polypropylene Film have been widely recognized by leading companies across different sectors. {} has built a strong reputation for delivering reliable and innovative packaging solutions, and the Metallized Polypropylene Film is a testament to their commitment to excellence.In addition to its exceptional product offerings, {} also takes pride in its customer-centric approach and dedication to providing outstanding service to its clients. The company works closely with customers to understand their specific packaging needs and offers customized solutions tailored to their requirements.The company's team of experts and engineers are constantly pushing the boundaries of innovation to develop cutting-edge packaging solutions that meet the evolving demands of the industry. With a focus on research and development, {} continues to introduce new and improved products that set the benchmark for quality and performance in the packaging market.As the demand for reliable and sustainable packaging solutions continues to grow, {} remains at the forefront of the industry, setting new standards and redefining the future of packaging. The company's unwavering commitment to excellence, innovation, and customer satisfaction has established them as a trusted partner for businesses looking to elevate their packaging standards.In conclusion, Metallized Polypropylene Film is a testament to the relentless pursuit of excellence and innovation by {}. With its exceptional performance, sustainability, and versatility, this film has become a go-to solution for companies looking to enhance the quality and shelf life of their products. As {} continues to lead the way in the packaging industry, businesses can rest assured that they are investing in top-notch solutions that will set them apart in the market.