Top Benefits of Matte Finish Polyester Film for Various Applications

By:Admin

The Matte Finish Polyester Film is a high-quality, durable, and versatile product that offers a smooth and luxurious matte appearance. It is designed to provide excellent clarity and performance for a wide range of applications, including packaging, labels, printing, and lamination. The film is also available in a variety of thicknesses and widths to accommodate different customer requirements.

One of the key features of the Matte Finish Polyester Film is its excellent printability, making it suitable for both flexographic and gravure printing processes. This ensures that the film can be customized with various designs, colors, and finishes to meet the specific branding and marketing needs of different companies and industries. Additionally, the film offers exceptional ink adhesion and scratch resistance, ensuring that the printed designs remain crisp and vibrant throughout the product's lifecycle.

The Matte Finish Polyester Film also offers excellent barrier properties, making it suitable for packaging applications where product protection and shelf appeal are crucial. It provides a reliable barrier against moisture, oxygen, and other external factors, helping to preserve the quality and freshness of the packaged products. This makes it an ideal choice for food, pharmaceutical, and personal care product packaging.

As a leading provider in the film industry, [Company Name] is committed to delivering products that meet the highest standards of quality and performance. The new Matte Finish Polyester Film is manufactured using state-of-the-art production facilities and processes, ensuring consistency and reliability in every roll. The company also places a strong emphasis on sustainability and environmental responsibility, ensuring that the film is manufactured in compliance with the highest industry standards for safety and sustainability.

The addition of the Matte Finish Polyester Film to [Company Name]'s product line further strengthens its position as a one-stop solution for film and packaging needs. With a comprehensive range of products and a commitment to innovation and customer service, the company continues to be a trusted partner for businesses across various industries. The company's experienced team of experts is also available to provide technical support, product recommendations, and customized solutions to help customers achieve their specific packaging and printing goals.

In addition to the Matte Finish Polyester Film, [Company Name] offers a wide range of other film products, including BOPP film, PET film, and specialty films for specific applications. The company's expertise and capabilities also extend to converting, slitting, and packaging services, providing customers with a complete solution for their film and packaging needs.

With the introduction of the new Matte Finish Polyester Film, [Company Name] is poised to further strengthen its position as a leading provider of high-quality film products for various industries. The company's commitment to innovation, quality, and customer satisfaction ensures that it remains at the forefront of the film manufacturing industry, meeting the evolving needs of its customers and delivering value through its diverse range of products and services.

Company News & Blog

Durable and Fireproof Insulation Boards: Everything You Need to Know

Fireproof Insulation Boards are quickly gaining popularity in the construction industry due to their excellent fire-resistant properties and efficient insulation capabilities. These innovative boards offer a range of benefits, making them an ideal choice for both residential and commercial construction projects.One of the leading manufacturers of Fireproof Insulation Boards is a company that has been at the forefront of innovation in the construction materials industry for over two decades. With a focus on quality and sustainability, this company has established itself as a trusted supplier of high-performance building materials.Their Fireproof Insulation Boards are designed to provide exceptional fire protection, making them an ideal choice for buildings that require high levels of safety and security. These boards are manufactured using advanced technology and high-quality materials, ensuring that they meet the highest industry standards for fire resistance.In addition to their fireproof properties, these insulation boards also offer excellent thermal insulation, helping to improve energy efficiency in buildings. This can lead to lower energy costs and reduced environmental impact, making them a sustainable choice for construction projects.Furthermore, these Fireproof Insulation Boards are lightweight and easy to install, reducing construction time and labor costs. They are also versatile and can be used in a variety of applications, including walls, ceilings, and floors.The company takes pride in its commitment to sustainability, and their Fireproof Insulation Boards are no exception. These boards are made from environmentally friendly materials and are fully recyclable, minimizing their impact on the environment.With a strong emphasis on research and development, this company continues to innovate and improve its products. Their Fireproof Insulation Boards are continuously tested and improved to ensure they meet the evolving needs of the construction industry.In addition to their high-quality products, the company also provides excellent customer service and technical support. Their team of experts is readily available to offer guidance and assistance to architects, contractors, and developers, helping them choose the right insulation solutions for their specific project requirements.The demand for fireproof insulation boards is on the rise, and this company is well-equipped to meet the increasing needs of the market. With a commitment to excellence and sustainability, they are poised to remain a leader in the production of high-performance building materials.Overall, Fireproof Insulation Boards from this company offer a compelling solution for construction projects that require superior fire protection and efficient insulation. With their exceptional performance, sustainability, and commitment to customer satisfaction, these insulation boards are set to make a lasting impact on the construction industry. As the demand for fire-resistant building materials continues to grow, this company is well-positioned to meet the needs of the market with its innovative and high-quality Fireproof Insulation Boards.

The Importance of High-Quality Insulating Paper in Electrical Equipment

Insulating Paper Continues to Innovate for a Sustainable FutureInsulating paper is an essential component in a wide variety of industries, including electric motors, transformers, capacitors, and generators. These products rely on insulating paper to provide electrical insulation, ensuring safe and reliable performance. For decades, Insulating Paper, a global leader in the production of insulating paper, has been at the forefront of innovation, continually pushing the boundaries of what is possible through cutting-edge research and development.Founded more than 50 years ago, Insulating Paper has established itself as a trusted name in the industry, recognized for its commitment to quality, reliability, and sustainability. As a family-owned company, Insulating Paper takes pride in its long-term vision, focusing on investments in research and development to continually improve its products and services.One of the company's most recent innovations is a new line of products designed to meet the growing demand for sustainability in the industry. With increasing pressure to reduce waste, energy consumption, and emissions, customers are seeking more eco-friendly solutions for their insulation needs. Insulating Paper has responded by developing a range of insulating paper products that are made from sustainable materials and are recyclable.The new products are made from a blend of natural fibers and synthetic materials, providing a balance of strength and flexibility while reducing the environmental impact of the production process. The use of natural fibers not only reduces the use of synthetic materials but also makes the paper more biodegradable, reducing waste at the end of its life.Insulating Paper has also been investing heavily in renewable energy to power its production plants. By switching to renewable energy sources, such as wind and solar power, the company has been able to reduce its carbon footprint significantly."Part of our commitment to sustainability is to minimize the impact of our operations on the environment," said the company's CEO. "We believe that by investing in renewable energy and sustainable materials, we can create a more sustainable future for ourselves and our customers."In addition to its sustainability initiatives, Insulating Paper continues to drive innovation in product development. One of the company's most significant breakthroughs is a new type of insulating paper that incorporates nanotechnology. The new paper, which is still in the research phase, has been shown to increase the insulation performance of electrical equipment significantly."Our goal is always to develop products that provide our customers with the best possible performance and reliability while also reducing their environmental impact," said the CEO. "The use of nanotechnology in our insulating paper has the potential to revolutionize the industry by offering much-improved performance in a more sustainable way."With its commitment to sustainability and innovation, Insulating Paper is well-positioned for growth in the years ahead. As the demand for sustainable products continues to rise, the company's focus on sustainability will help ensure that it remains a trusted supplier to its customers."We believe that sustainability is not just good for the environment, it's also good for business," said the CEO. "By providing eco-friendly solutions to our customers, we can create value while also creating a more sustainable future for everyone."In conclusion, Insulating Paper is a company committed to innovation, sustainability, and customer satisfaction. With its focus on research and development, Insulating Paper continues to push the boundaries of what is possible in insulating paper products, offering improved performance and reliability while reducing their environmental impact. As the industry continues to evolve, Insulating Paper will remain at the forefront, offering sustainable solutions to meet the needs of its customers for years to come.

New Breakthrough Treatment for Targeted Lung Cancer Therapy Unveiled

Alectinib, a novel and potent anaplastic lymphoma kinase (ALK) inhibitor, has made significant strides in the treatment of non-small-cell lung cancer (NSCLC) patients. The drug has been approved by major regulatory agencies worldwide and continues to undergo various clinical trials. Alectinib has shown superior clinical results when compared to other available ALK inhibitors, including crizotinib, making it a preferred treatment option.Alectinib, marketed under the brand name Alecensa, works by selectively blocking mutations in the ALK gene, which is present in around 3-7% of NSCLC cases. When the ALK gene becomes mutated, it leads to the production of an abnormal ALK protein, which triggers uncontrolled cancer growth. Alecensa binds to the ALK protein, inhibits its activity, and halts the signaling pathway, effectively controlling the growth and spread of cancerous cells.Alecensa was developed by Chugai Pharmaceutical, a Japanese pharmaceutical company founded in 1925 and is headquartered in Tokyo. Chugai Pharmaceutical specializes in developing innovative medications for oncology, as well as various forms of joint diseases and other medical conditions. The company prioritizes research and discovery as the means of creating sustainable solutions to global health challenges.Clinical trials of Alecensa have proven successful in treating NSCLC patients, particularly those diagnosed with ALK-positive lung cancer. The drug has demonstrated effective control of brain metastases, a common complication of NSCLC. In a phase III trial, Alecensa showed superior results in preventing cancer progression and improving progression-free survival (PFS) compared to Crizotinib, the existing standard of care. Alecensa also displayed a reduced risk of relapse or death, which translates to better overall survival (OS) for NSCLC patients.The drug's efficacy is not limited to patients who have previously undergone chemotherapy. Alecensa has a higher response rate and induces fewer side effects in comparison to other treatments. Its ability to cross the blood-brain barrier was highly appreciated as well. The medication was approved by the U.S. Food and Drug Administration (FDA) in December 2015, while the European Medicines Agency (EMA) approved it in February 2017.Alecensa's success has made Chugai Pharmaceutical a prominent player in the global oncology market as the population of lung cancer patients continues to rise. Chugai Pharmaceutical has pledged to continue in-depth research of Alecensa to understand better how to improve the drug's efficacy and the range of cancer types it can treat. Taking a patient-centric approach, the company focuses on not only drug discovery but also advocacy and support for cancer patients, improving their quality of life.The efficacy of an ALK inhibitor such as Alecensa displays the impact pharmaceuticals can have on the treatment of cancers. The drug's discovery and development have saved patients previously given unimpressive prognoses and offers a better alternative to other treatment options. Chugai Pharmaceutical is dedicated to improving access to the drug to make it available for a more extensive range of patients worldwide.In conclusion, Alecensa has become a standard in the treatment of ALK-positive NSCLC, offering better outcomes in terms of PFS and OS. Its minimal side effects position it as more favourable when compared to other treatment options. The drug epitomises the importance and potential of medical research and available treatments. It is evident that Chugai Pharmaceutical's continued efforts to research, support and improve Alecensa will only mean better outcomes for lung cancer patients.

Unlock the Secrets of the F-Class Dm: Expert Insights on Dominating Your Field

McKinney, Texas – Worldwide leading provider F-Class Dm announced the latest addition to their product line – the F-Class Dm. The company leveraged their long-standing expertise in engineering mechanical equipment and technology to develop this new model. This powerful, reliable, and user-friendly machine demonstrates the company’s commitment to innovation and meeting the changing needs of clients across industries.F-Class Dm is an affordable and versatile machine with the ability to work with a broad range of materials, from metals to composites. With its advanced technological features, this heavy-duty machine is designed to handle heavy-duty projects with the greatest precision while reducing production costs.The production of the F-Class Dm is guided by the company's principle of excellence in engineering. Every component of the machine is carefully crafted with high-quality materials to ensure that it fulfills the rigorous performance requirements of various industries and applications. With Synchronous Servo Technology, this machine provides precise operation, reducing downtime, and waste. It also features a programmable Logic Controller (PLC), which enables seamless automation and high-level of control.F-Class Dm is the perfect solution for a variety of industries, from aerospace to automotive to general industrial applications. Aerospace companies working on the production of aerospace components can use this machine to create precision parts with high structural integrity. On the other hand, automotive manufacturers can leverage the features of the F-Class Dm to produce components with improved toughness and wear resistance.Furthermore, companies in metalworking, mold making, and general industrial applications can benefit from this machine's capabilities. F-Class Dm is ideal for creating intricate components with high dimensional accuracy and consistency, reducing scrap and rework. With the ease of operation, companies can increase production output, ensuring timely delivery of products to their customers."This new addition to our already top-rated product line of mechanical machines provides our clients with an affordable and reliable solution for various applications,” said the company spokesman during the product launch. "We're committed to engineering the finest equipment in this industry and providing unique solutions to meet our clients' needs."For over two decades, F-Class Dm has been a leading provider of mechanical machines engineering. They are known for their expertise in providing top-of-the-line equipment, innovative design, and exceptional customer support. The company guarantees exceptional quality, performance, and precision of every machine they manufacture.F-Class Dm provides solutions to clients worldwide, and their products have earned a reputation for being dependable and efficient. With the addition of the F-Class Dm, clients can expect superior performance and efficiency at an affordable price. Furthermore, the comprehensive engineering support the company offers will provide maximum uptime, increasing efficiency, and reducing overall operating costs.In conclusion, the F-Class Dm is a valuable addition to F-Class Dm's lineup of mechanical machines. It combines advanced features, quality components, and superior engineering to deliver the best performance in various applications. With the high precision and reliability of this machine, clients can increase their production output, reduce operational costs, and expand their capabilities.

Frosted Polycarbonate Film: Ideal for Various Applications

Title: Innovative Frosted Polycarbonate Film Paves the Way for Versatile ApplicationsIntroduction:In today's rapidly evolving market, industries are constantly seeking innovative materials that push the boundaries of design and functionality. Enter a renowned company - a leader in polycarbonate film manufacturing - that has recently launched an extraordinary product: Frosted Polycarbonate Film. With its myriad of applications and potential to revolutionize various industries, this film is set to take the market by storm.Paragraph 1:Frosted Polycarbonate Film, introduced by the esteemed manufacturing company, is a breakthrough material that offers exceptional versatility and functionality. With its unique frosted finish, this translucent film provides a stunning aesthetic appeal while simultaneously delivering superior performance. It is fabricated using cutting-edge technology, ensuring durability, flexibility, and remarkable optical characteristics.Paragraph 2:One major advantage of Frosted Polycarbonate Film lies in its wide range of applications across multiple industries. In architecture and interior design, this film can transform ordinary glass surfaces into elegant privacy screens, making it an excellent choice for office spaces, retail stores, and residential areas. Its frosted appearance diffuses light, reducing glare and creating a comfortable ambiance.Paragraph 3:The film's exceptional durability and resistance to scratches make it an ideal choice for signage and display applications. Frosted Polycarbonate Film can be easily printed on, enabling businesses to showcase their branding or promotional messages with a professional and captivating appearance. Additionally, this material can withstand outdoor environments, ensuring longevity in various weather conditions.Paragraph 4:The automotive industry can also benefit from Frosted Polycarbonate Film. It provides privacy and heat reduction when applied to car windows, enhancing the driving experience while maintaining a sleek and sophisticated look. Moreover, its lightweight nature significantly contributes to the vehicle's overall fuel efficiency.Paragraph 5:Beyond architecture and automotive applications, Frosted Polycarbonate Film has immense potential in the electronics industry. With its superior light diffusion properties, it can be used as a display cover for electronic devices, ensuring optimal visibility in different lighting conditions. Moreover, its high impact resistance protects fragile screens from accidental damage.Paragraph 6:The company's commitment to sustainability is also evident in the production process of Frosted Polycarbonate Film. The film is manufactured using environmentally friendly practices, minimizing waste and reducing carbon footprint. Its durability and long lifespan contribute to the conservation of resources, making it an eco-friendly choice for conscious consumers.Paragraph 7:In conclusion, the introduction of Frosted Polycarbonate Film by the esteemed manufacturing company is set to revolutionize various industries. This innovative material offers a versatile range of applications, from architectural privacy solutions to automotive enhancements and electronic devices. With its exceptional durability, aesthetic appeal, and sustainable production process, Frosted Polycarbonate Film is poised to become the go-to choice for industries seeking cutting-edge, high-performance materials.

Understanding the Benefits of Mono-Oriented Polypropylene Film: A Comprehensive Guide

Title: Mono Oriented Polypropylene Film Revolutionizes Packaging IndustryIntroductionIn an increasingly competitive market, the demand for innovative and high-quality packaging solutions continues to rise. The introduction of Mono Oriented Polypropylene (MOPP) film has brought significant advancements, delivering superior functionalities and enhancing packaging aesthetics. This article delves into the features and benefits of MOPP film, exploring its potential to revolutionize the packaging industry.Understanding Mono Oriented Polypropylene FilmMono Oriented Polypropylene film is a versatile and flexible packaging material widely used across various industries due to its exceptional properties. Crafted through a specialized manufacturing process, MOPP film offers superior strength, clarity, and chemical resistance compared to other films.Key Benefits of MOPP Film1. Enhanced Clarity and Printability: MOPP film provides excellent transparency, enabling vivid colors and designs to be displayed on packages. This feature is especially vital for product packaging as it attracts consumers' attention and increases product visibility on the shelves.2. Optimal Barrier Protection: The film's barrier properties prevent oxygen, moisture, and other external contaminants from penetrating the packaged goods. This protective feature extends the shelf life of perishables, ensuring product freshness and quality over an extended period.3. Exceptional Strength and Durability: MOPP film possesses remarkable tear and puncture resistance, safeguarding the integrity of the packaged goods during storage and transportation. This strength makes it an ideal choice for packaging products such as snacks, pet food, and pharmaceuticals.4. Chemical Resistance: MOPP film exhibits excellent resistance to chemicals, oils, and solvents, ensuring compatibility with a wide range of products. This feature makes it particularly suitable for packaging products such as cleaning agents, cosmetics, and automotive fluids.Applications in Various Industries1. Food and Beverage: MOPP film's exceptional barrier properties make it an ideal choice for packaging food and beverages. Its transparency enhances product visibility, while its chemical resistance ensures no cross-contamination. From snack packaging to coffee bags, MOPP film guarantees optimal freshness and protection.2. Pharmaceutical and Medical: MOPP film's strength and chemical resistance make it an excellent choice for packaging pharmaceutical products. It protects drugs from moisture, UV exposure, and other external factors that could affect their potency. Moreover, MOPP film complies with strict regulatory standards, ensuring the safety and integrity of medical products.3. Personal Care and Cosmetics: MOPP film's clarity and printability enable captivating packaging designs for personal care and cosmetic products. Its barrier properties prevent product deterioration and contamination, guaranteeing a longer shelf life for these items.The Future of MOPP FilmMOPP film's usage in the packaging industry is expected to grow substantially in the coming years. As consumer preferences continue to evolve, the demand for sustainable packaging options rises. MOPP film, being recyclable, is aligned with these growing environmental concerns. Additionally, advancements in manufacturing technology are further improving the film's properties, including increased thickness options and sealability.ConclusionMono Oriented Polypropylene film has revolutionized the packaging industry with its exceptional properties and versatility. Offering enhanced clarity, barrier protection, exceptional strength, and chemical resistance, MOPP film is an ideal choice for various industries, including food and beverage, pharmaceuticals, and personal care. As the demand for sustainable packaging options continues to increase, MOPP film is expected to play a crucial role in meeting these requirements. With its ongoing innovations, MOPP film stands poised to shape the future of the packaging industry.

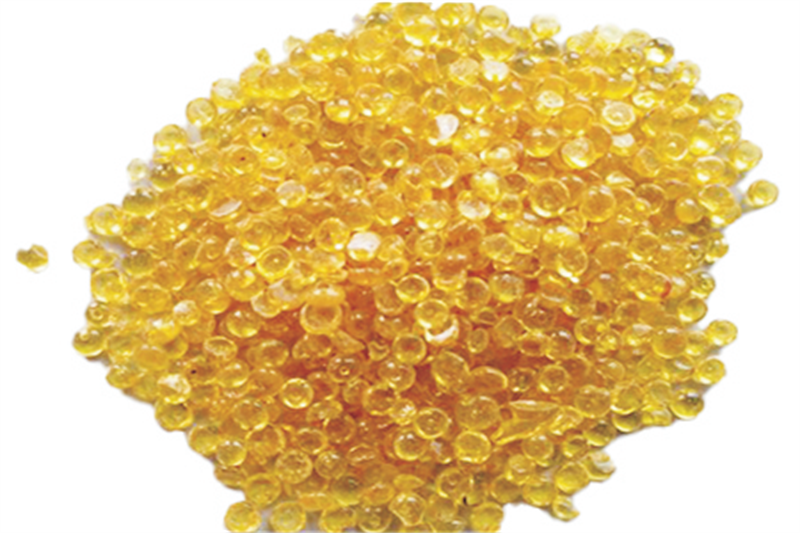

Hydrogenated Hydrocarbon Resin Market Sees Growth Amid Increasing Demand

Recently, C9 Hydrogenated Hydrocarbon Resin, a high-quality resin product, has been making waves in the chemical industry. This exceptional product is made with state-of-the-art technology and comes with a distinct set of features that has made it a popular choice among manufacturers.C9 Hydrogenated Hydrocarbon Resin has been designed to meet the growing demands of the industry. It is an excellent raw material for adhesives, coatings, hot melt adhesives, and rubber mixing. This product provides improved compatibility, tackiness, and adhesion strength, making it a versatile choice for a variety of applications.Manufactured by a top-class company, this product is backed by years of experience and expertise in the chemical industry. The company is dedicated to developing the highest quality of chemical products that can meet the evolving needs of the market. The introduction of C9 Hydrogenated Hydrocarbon Resin is just one of many examples of this dedication.Manufacturers can rely on the consistent quality of this product, which is made with a precise formula and manufacturing process. C9 Hydrogenated Hydrocarbon Resin comes in various grades and specifications, allowing manufacturers to pick the product that suits their needs the best. These grades differ in terms of the softening point and viscosity, which determine the product's suitability in different applications.One of the most exceptional features of C9 Hydrogenated Hydrocarbon Resin is its high thermal stability. This makes the product highly resistant to thermal degradation, which is essential in applications involving high temperatures. Additionally, this product has superior light fastness, which makes it more stable against UV light.Moreover, C9 Hydrogenated Hydrocarbon Resin has excellent solubility making it easy to dissolve in different solvents. This property contributes to its versatility and makes it a suitable candidate for different formulations.The applications of C9 Hydrogenated Hydrocarbon Resin are vast, ranging from adhesives to coatings to hot melt adhesives. As a raw material, this product enhances the tackiness of adhesives, improves the cohesiveness of coatings, and provides rubber mixtures with better adhesion properties. It is suitable for use in the paper and packaging industry, the building and construction industry, and various other manufacturing sectors.Moreover, the manufacturing process of C9 Hydrogenated Hydrocarbon Resin adheres to strict quality standards, ensuring that the final product is of the highest standard. To maintain the quality and consistency of each batch produced, the company conducts quality checks at every stage of the manufacturing process. This approach makes C9 Hydrogenated Hydrocarbon Resin a trustworthy and reliable product to use in any manufacturing process.In conclusion, C9 Hydrogenated Hydrocarbon Resin is an excellent product that provides numerous benefits to manufacturers. With its superior properties, it has proved to be a popular choice in several industries. The manufacturing process of this product adheres to strict quality standards, making it a reliable choice for use in various manufacturing processes. As the industry continues to evolve, C9 Hydrogenated Hydrocarbon Resin plays a crucial role in providing manufacturers with a versatile, high-quality raw material.

Top Insulating Materials for High-Temperature Applications

Insulating Parts Revolutionize Energy Efficiency: (Need to remove brand name) Launches Cutting-Edge SolutionsIn today's rapidly evolving world, energy efficiency has become a critical concern for businesses and households alike. The need to reduce energy consumption, lower greenhouse gas emissions, and save on costs has propelled efforts to innovate in various sectors. In this context, (Remove brand name), a pioneering company in the field of advanced insulation technology, is introducing groundbreaking solutions that promise to revolutionize energy efficiency.With a long-standing reputation as an industry leader and a commitment to sustainable practices, (Remove brand name) has built a solid foundation for its latest product line. These insulating parts are at the forefront of energy-saving technologies and hold the potential to significantly impact energy consumption patterns across industries.The secret behind (Remove brand name)’s insulating parts lies in a combination of cutting-edge materials, meticulous engineering, and a deep understanding of thermal dynamics. By effectively reducing heat transfer and minimizing energy losses, these innovative solutions are set to redefine energy efficiency standards.The development of (Remove brand name)’s insulating parts has been years in the making. R&D teams have worked tirelessly to improve existing technologies and develop new approaches, resulting in an array of products that cater to the diverse needs of different sectors.One of the key advantages of these insulating parts is their versatility. Whether used in manufacturing plants, commercial buildings, or residential homes, they provide effective insulation, irrespective of the application. This adaptability ensures that businesses and individuals can rely on the same level of thermal efficiency across various settings.Moreover, (Remove brand name)’s insulating parts have been designed to be lightweight and easy to install. The company understands the importance of minimizing disruption during implementation, especially in commercial and industrial settings where time is of the essence. The user-friendly design allows for efficient installation without compromising on performance, making it a hassle-free experience for the end-users.Beyond their obvious energy-saving benefits, (Remove brand name)’s insulating parts also contribute to a reduction in greenhouse gas emissions. By preventing heat loss or gain, they support the use of clean and renewable energy sources, further enhancing their significance in the ongoing fight against climate change.To make these cutting-edge products accessible to a wider audience, (Remove brand name) has ensured that they comply with industry standards and regulations. Extensive testing and certification ensure that businesses and individuals can confidently adopt these insulating parts, knowing that they meet the necessary requirements for energy efficiency and safety.But (Remove brand name) is not just a company that offers innovative products; it is also committed to sustainable practices across its operations. Recognizing the urgency of the climate crisis, (Remove brand name) has taken significant steps to reduce its carbon footprint and promote a greener future. The company's manufacturing processes prioritize the use of recycled materials and aim for minimal waste generation. By leading by example, (Remove brand name) actively demonstrates its commitment to a sustainable and energy-efficient future.With the launch of their groundbreaking insulating parts, (Remove brand name) has firmly established itself as a pioneer in the field of energy efficiency. By harnessing the power of advanced insulation technology, this innovative company offers a viable solution to combat rising energy consumption and reduce greenhouse gas emissions.As industries and individuals increasingly prioritize energy efficiency, (Remove brand name)’s insulating parts provide an invaluable tool to achieve sustainability goals. By reducing energy costs, minimizing carbon footprints, and ensuring thermal comfort, these products empower businesses and households alike to make a positive impact on the environment.

Exploring the Benefits and Applications of Phenolic Epoxy Resin: All You Need to Know

Title: Revolutionary Biphenyl Phenolic Epoxy Resin Redefines Industrial CoatingsIntroduction:In the bustling world of industrial coatings, a groundbreaking development has emerged. A prominent company, renowned for its advanced materials, has unveiled its latest innovation – a Biphenyl Phenolic Epoxy Resin (BPPE). This dynamic product is set to revolutionize the industry with its superior properties and environmentally-friendly qualities.[Company Name], a leader in materials research and development, has long been committed to offering cutting-edge solutions to various industries. Their expertise in formulating high-performance materials has earned them a strong reputation worldwide. With the introduction of BPPE, they continue to establish themselves as pioneers in the field.Biphenyl Phenolic Epoxy Resin: A Game-Changing Material:BPPE is a significant breakthrough due to its exceptional characteristics and versatility. Acting as an essential ingredient for numerous commercial and industrial applications, this resin brings superior performance and durability to a wide range of products.The key attributes of BPPE that set it apart from conventional resins are its outstanding chemical resistance, excellent adhesion capabilities, and superior mechanical strength. These properties make it ideal for use in industrial coatings, where robust protection against environmental factors, including moisture, chemicals, and corrosion, is crucial.Moreover, BPPE establishes a new standard when it comes to eco-friendliness. Unlike many traditional resins that contain harmful volatile organic compounds (VOCs), this resin is specifically formulated to minimize such emissions, making it environmentally responsible and safe for both workers and consumers.Applications and Benefits:The applications of BPPE are extensive and varied, making it a versatile material capable of enhancing diverse industries. Some notable applications include:1. Protective Coatings for Industrial Equipment:BPPE is ideal for providing an extra layer of protection to critical industrial equipment. It ensures longevity, durability, and resistance against harsh conditions, safeguarding valuable assets.2. Anti-Corrosion Solutions:By virtue of its excellent resistance to corrosion, BPPE-based coatings prove highly effective in safeguarding metal surfaces exposed to moisture, acids, and other corrosive substances. This resilience extends the lifespan of the materials, reduces maintenance costs, and enhances overall efficiency.3. Marine Coatings:The maritime industry heavily relies on coatings that can withstand the harsh marine environment. BPPE-based coatings offer exceptional resistance to saltwater, UV radiation, and extreme temperatures, significantly reducing maintenance expenses and enhancing the durability of marine structures.4. Construction Sector:The construction sector greatly benefits from BPPE-based coatings due to their excellent adhesion and chemical resistance properties. BPPE protects surfaces from weathering, abrasion, and chemical damage, ensuring the durability of structures exposed to diverse environmental conditions.In addition to these applications, BPPE finds use in the electrical industry, transportation, and various other sectors where robust protective coatings are required.Conclusion:In an era where advanced materials can make all the difference, Biphenyl Phenolic Epoxy Resin emerges as a game-changer in industrial coatings. With unrivaled chemical resistance, superb adhesion capabilities, and exceptional durability, this revolutionary resin offers extensive applications across industries.[Company Name] has once again demonstrated its commitment to innovation by introducing this cutting-edge material to the market. The environmentally-friendly nature of BPPE further cements its status as a groundbreaking solution for diverse coating needs. As multiple sectors benefit from the extraordinary properties of BPPE, it is expected to redefine industrial coatings and reshape the landscape of the global materials industry.

Market for Polycarbonate Film and Plastic Film in China Sees Growth

China Polycarbonate Film and Polycarbonate Plastic Film Companies Collaborate to Win the Global MarketChina, August 2021 - Two leading Chinese manufacturers of polycarbonate film and polycarbonate plastic film have joined forces to capture global market share. The partnership of these two companies promises to be a game-changer in the industry as they combine their strengths to create innovative, high-quality products. Their goal is to offer customers a wider range of products with improved functional and aesthetic features that can meet the most demanding requirements of discerning consumers.The collaboration of these two companies represents a significant development in the polycarbonate film and polycarbonate plastic film market in China. The companies bring together their technical expertise, innovative spirit, and market insight, with the aim of creating high-tech products that meet consumers' needs for durable, high-performance materials. The new partnership will enable rapid response to new challenges and market trends and provide a superior customer experience.The companies are recognized for their accomplishments in the field of polycarbonate film and polycarbonate plastic film production. Their products are sold to customers across a wide range of industries including electronics, automotive, packaging, and medical applications. With years of experience in the polycarbonate film industry, they have gained a reputation for high-performance materials, prompt delivery, and exceptional customer service.The companies' products have earned numerous awards and accolades for their high-quality, innovation, and sustainability. The new collaboration will ensure that product innovations continue to meet and exceed customers' expectations. The companies' dedication to sustainability, eco-friendliness, and the circular economy is reflected in their processes, products and commitment to reducing environmental impact. Compatible with high-performance composites, coatings, adhesives, and other advanced materials, the companies' products offer versatility, flexibility, and reliability.The partnership between the two companies is expected to provide customers with a more comprehensive range of products with a broader range of functional and aesthetic features. The companies plan to leverage their expertise to develop new technologies, products, and applications that can unlock new growth potential. Customers can expect benefits such as improved quality and performance, greater diversity, and more personalized options.The new collaborative business aims to achieve new heights in the polycarbonate film and polycarbonate plastic film industry. The companies will continue to provide customers with world-class products, backed by excellent customer service. The collaboration represents a significant shift in the competitive landscape of the polycarbonate film and polycarbonate plastic film market in China, with the potential to drive higher levels of innovation, growth, and customer satisfaction.The company has a customer-centric approach, ensuring that the needs of the customers are at the forefront of every decision. This philosophy is reflected in the quality of the products and the service levels provided to customers. The companies employ a highly skilled and experienced workforce, committed to innovation, collaboration, and excellence.The partnership between the two polycarbonate film and polycarbonate plastic film companies is a milestone that is poised to make a significant impact on the industry through their technological advancements and innovative products. By leveraging their respective strengths and capabilities, the two companies are positioned to meet the complex and evolving market demands and drive new growth potential in the polycarbonate film industry.The collaboration promises to bring new levels of product quality, sustainability, and affordability to customers. The two companies hail from different geographical regions in China pointing towards the growth of the industry in the country. With their combined industry knowledge, experience, and expertise, the companies seek to break new ground in product innovation, customer satisfaction and forge new pathways for success.In conclusion, the collaboration between these two companies in the polycarbonate film and polycarbonate plastic film industry is yet another sign of how China's manufacturing sector continues to evolve to meet global standards of excellence and innovation. With new levels of expertise and shared knowledge, they have positioned themselves to lead the way in the industry, driving innovation and bringing new opportunities to the global market. Their commitment to sustainability, customer service, quality, and innovation represents the gold standard for how polycarbonate film and polycarbonate plastic film manufacturers should operate in the industry.